- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

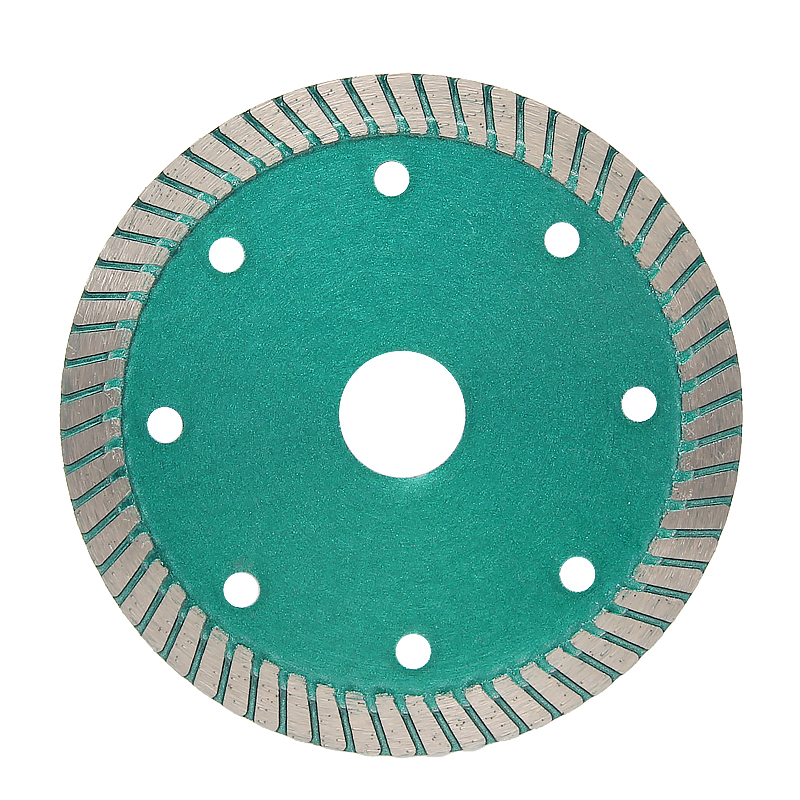

110 Ceramic Cutting Blades with Corrugated Teeth

- Category: Customized Series, Tile Cutting Blade

- |

- Date: 01/17/2025 23:34

110 Ceramic Cutting Blades with Corrugated Teeth

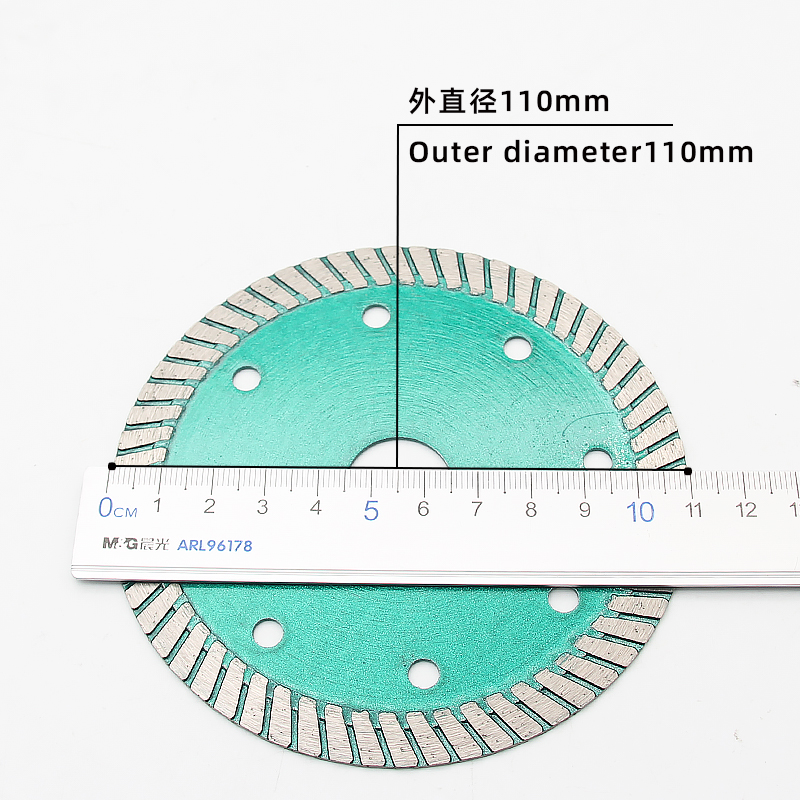

- Diameter: 110mm

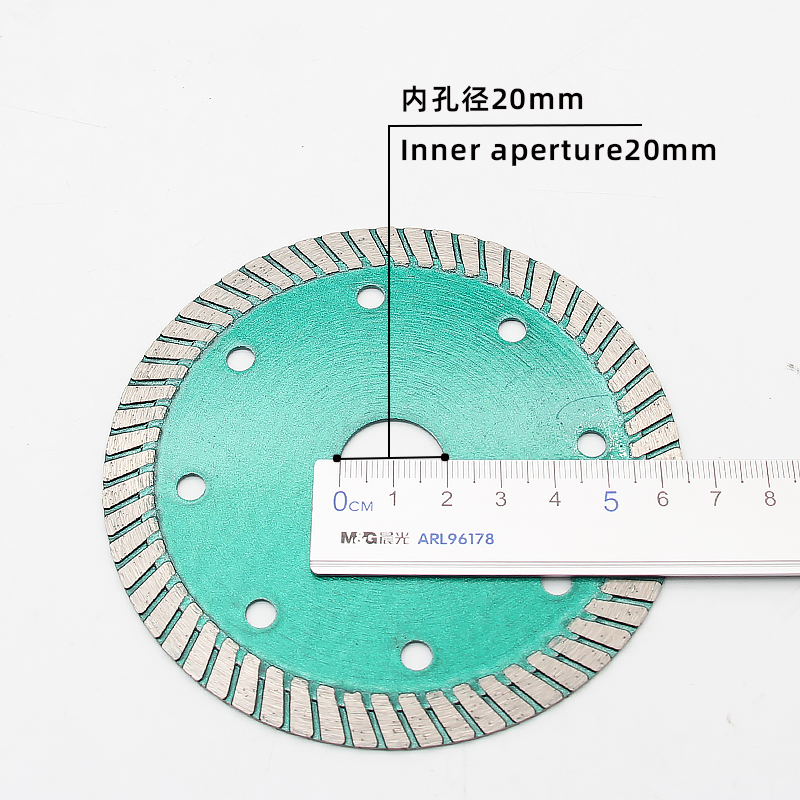

- Hole diameter: 20mm

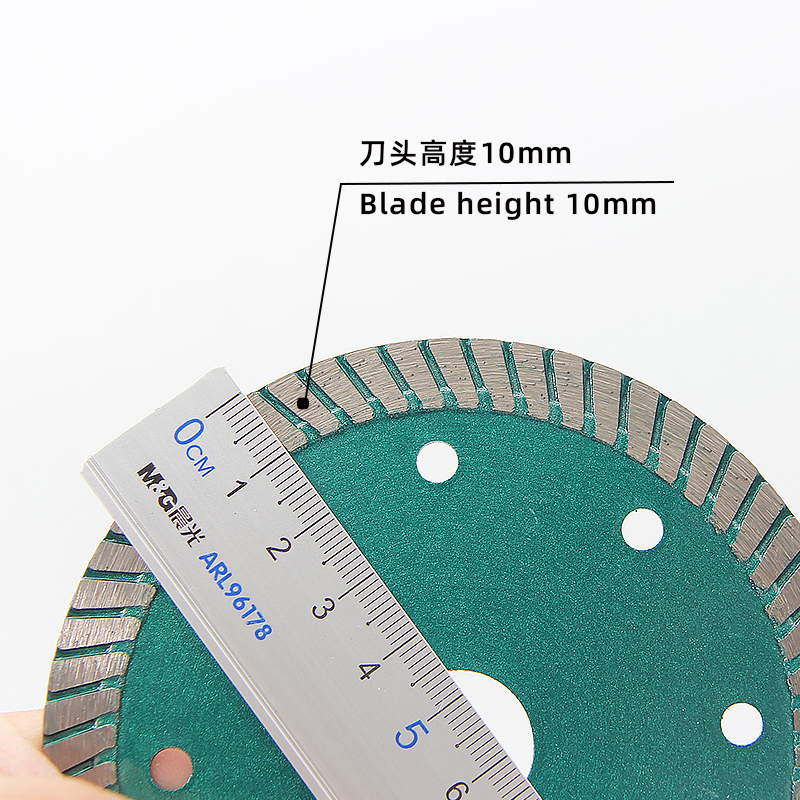

- Head height: 10mm

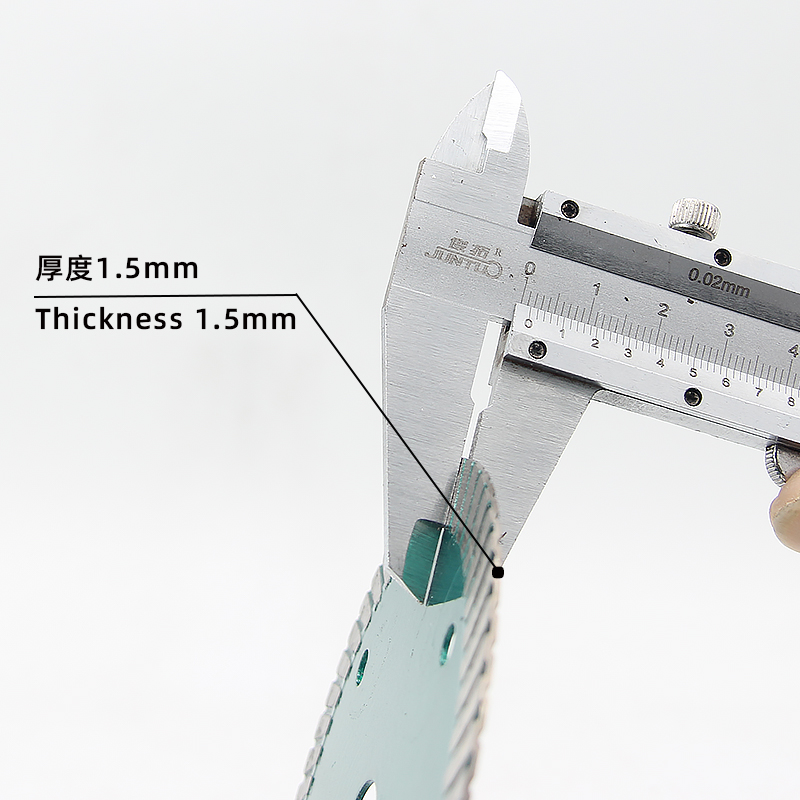

- Thickness: 1.1mm

- Place of origin: China, Shandong, Linyi

- Applications: ceramics, tiles, rock slabs, microcrystalline stone cutting.

Product Details

110 Corrugated Tooth Ceramic Cutting Blade is a tool specially designed for cutting hard materials such as ceramics:

I. Basic Concept

The ‘110’ in the name of the 110 corrugated tooth ceramic cutting blade usually refers to the diameter of the cutting blade, i.e. 110 mm. The ‘corrugated teeth’ describes the special design of the blade part of the cutting disc, which helps to enhance the cutting effect and improve the cutting efficiency.

Main features

High sharpness: The special design of corrugated teeth enables the cutting blade to cut into the material more easily during the cutting process and reduces cutting resistance.

High cutting efficiency: the corrugated teeth design not only improves the sharpness of the cutting blade, but also makes the cutting process smoother, thus improving the cutting efficiency.

Flat Cutting Surface: When cutting hard materials such as ceramics, the cutting discs are able to keep the cutting surface flat, reducing chipping and burrs.

Long service life: The high quality 110 corrugated tooth ceramic cutting discs are usually made of high quality materials, which have a long service life and can reduce the frequency and cost of replacing the cutting discs.

Third, the scope of application

110 corrugated teeth ceramic cutting blade is widely used in construction, decoration, manufacturing and other fields, especially suitable for cutting ceramic tiles, glass tiles, through-body tiles and other hard materials. In addition, it can also be used to cut stone, concrete, metal and other hard materials, but you need to choose the appropriate specifications of the cutting blade according to the hardness and thickness of the specific material.

Fourth, the use of precautions

Choose the right cutting disc: choose the right specification of cutting disc according to the hardness, thickness and size of the material to be cut.

Pay attention to the operation safety: when using the cutting disc, you should wear good protective equipment, such as protective glasses, masks and gloves. At the same time, ensure the stability and safety of the cutting machine to avoid accidents.

Keep the cutting blade clean: In the process of using, clean the debris and dust on the cutting blade in time to maintain the cutting effect and service life of the cutting blade.

Avoid overuse: the cutting blade will gradually wear out during use, and when it wears out to a certain extent, it should be replaced with a new one in time to avoid affecting the cutting effect and safety.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Testimonials

WeChat Code

Site Search

Related Products

Featured Articles

© 2025. All Rights Reserved.