- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

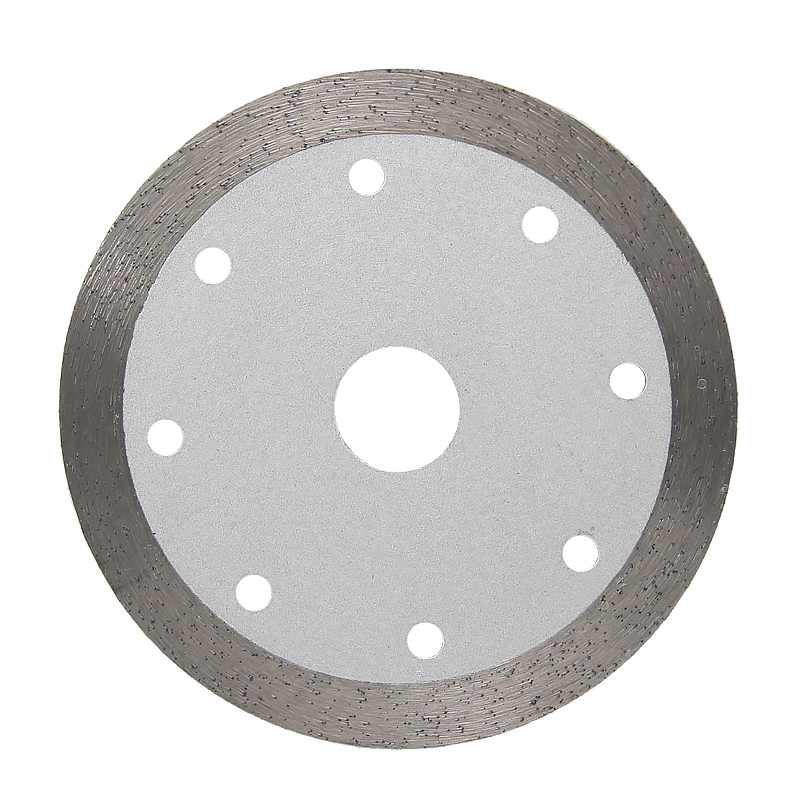

110 Continuous tooth cutterhead 10mm high

- Category: Products, Stone Cutting Blades

- |

- Date: 01/18/2025 21:43

110 Continuous tooth cutterhead 10mm high

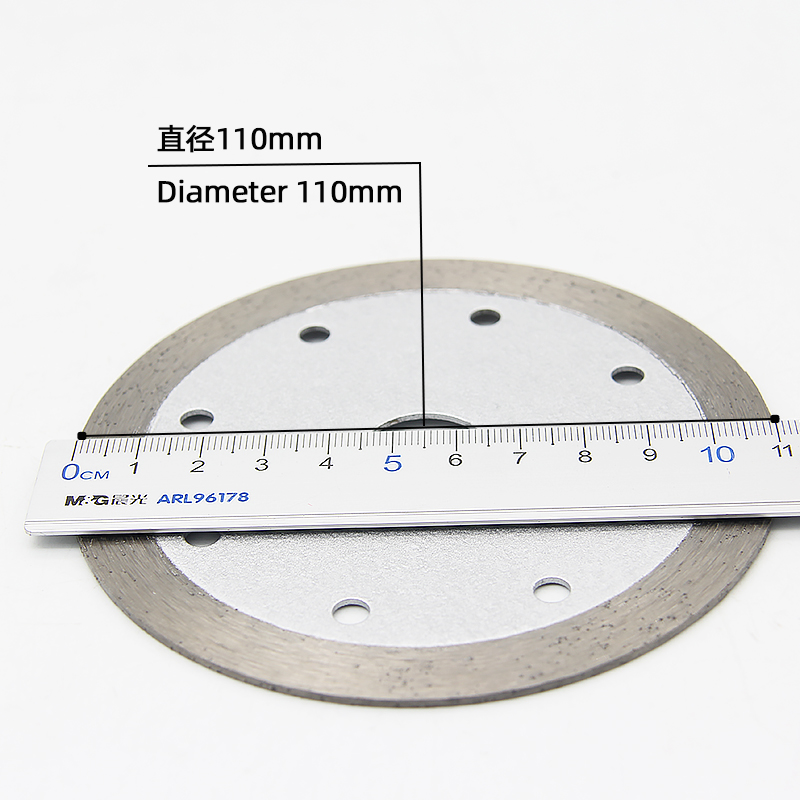

- Diameter: 110mm

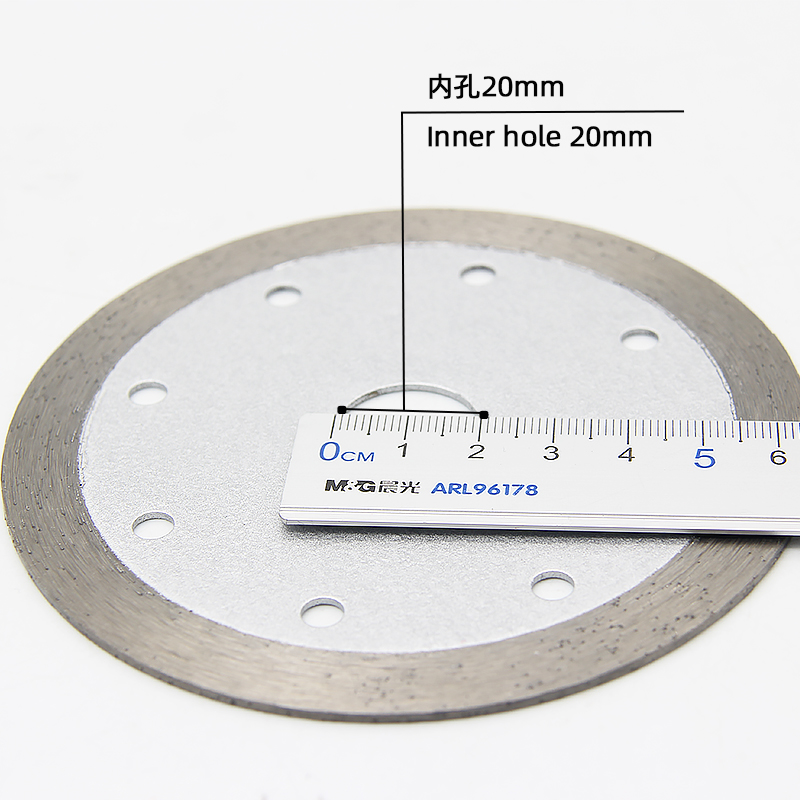

- Hole diameter: 20mm

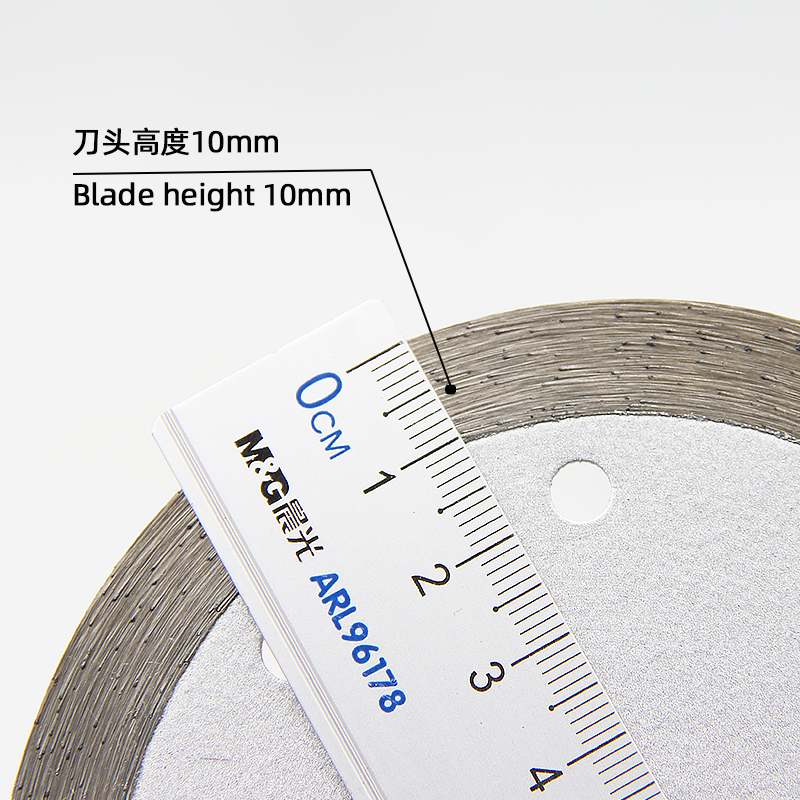

- Head height: 10mm

- Thickness: 1.8mm

- Place of origin: China, Shandong, Linyi

- Applications: granite, sandstone, rock slabs, marble cutting.

Product Details

110 Continuous Tip 10mm High Diamond Saw BladeProduct Description

In the field of stone processing, the performance of cutting tools is directly related to the processing efficiency and quality. Today, we would like to introduce you a highly acclaimed cutting tool in the industry – 110 Continuous Tip 10mm High Diamond Saw Blade.

Outstanding material for outstanding performance

This saw blade is made of diamond as the blade material. Diamond, one of the hardest substances in nature, gives saw blades superior wear resistance and cutting ability. When cutting marble and granite, which are the hardest stones, ordinary saw blades often seem to be unable to cope, while diamond saw blades can cope with it easily. Its high hardness makes the cutter head able to cut into the stone quickly, and in a long time during the cutting process, to maintain a stable cutting performance, reduce the cutting efficiency due to wear and tear caused by the problem of decline.

Knife body part, after careful design and selection of materials, with good toughness and rigidity. In the high-speed rotation cutting, can ensure the stability of the saw blade, to avoid shaking or deformation and so on, so as to ensure the precision of cutting and surface quality.

Unique design enhances cutting performance

The 110 continuous tooth design is one of the highlights of this saw blade. The distribution of continuous teeth makes the saw blade in the cutting process, can maintain continuous contact with the stone, cutting force is more uniform, to avoid the impact generated by the intermittent cutting, not only effectively reduce the risk of stone chipping, rupture, but also significantly improve the cutting speed and efficiency.

10mm high cutter head, compared with ordinary cutter head, has a longer service life. When cutting thick slabs of stone, there is no need to change the saw blade frequently, reducing downtime and further improving processing efficiency. At the same time, the height of the cutter head is also designed to take into full consideration of the heat dissipation problem, in the high-speed cutting of high temperature, can better dissipate the heat, to extend the overall service life of the saw blade.

Personalized customization to meet the diverse needs

We know that different customers have different needs in the stone processing process. For this reason, we provide professional customized services. Whether it is the diameter of the saw blade, the number of teeth, the height of the cutter head, or the concentration of diamond and other parameters, we can be customized according to the specific requirements of customers. Whether you need to cut special specifications of stone, or have specific requirements for cutting efficiency and quality, we can customize the most suitable saw blade for you.

Foreign trade export quality to win global recognition

With excellent quality and stable performance, this 110 Continuous Tip 10mm High Diamond Saw Blade has been successfully exported to many countries and regions. In the international market, it has won the trust and praise of many customers. We always adhere to strict quality control standards, from raw material procurement to production and processing, to finished product testing, each link is strictly controlled to ensure that each piece of saw blade meets international quality standards.

Choosing our 110 Continuous Tooth 10mm High Diamond Saw Blade is choosing an efficient, precise and durable stone cutting solution. Whether you are a large stone processing plant or a small stone processing enterprise, it will be your right hand to improve productivity and reduce costs. If you are interested in our products, please feel free to contact us, we will be happy to serve you.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Testimonials

Site Search

Product Center

Testimonials

Contact Us

© 2025. All Rights Reserved.