- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

110 Continuous Tooth Saw Blades for Wet and Dry Cutting

- Category: Products, Stone Cutting Blades

- |

- Date: 01/19/2025 13:56

110 Continuous Tooth Saw Blades for Wet and Dry Cutting

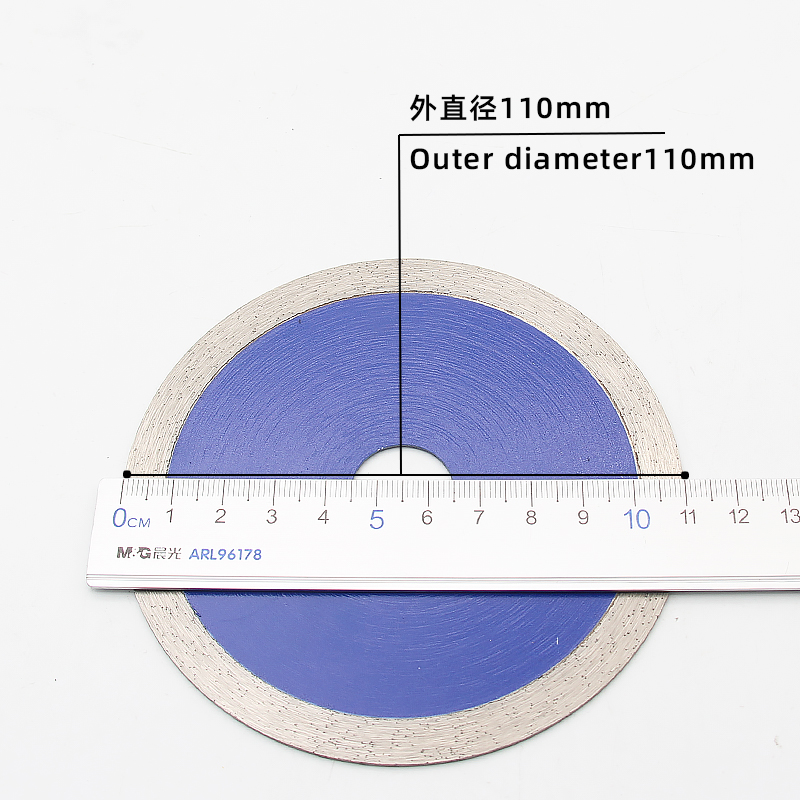

- Diameter: 110mm

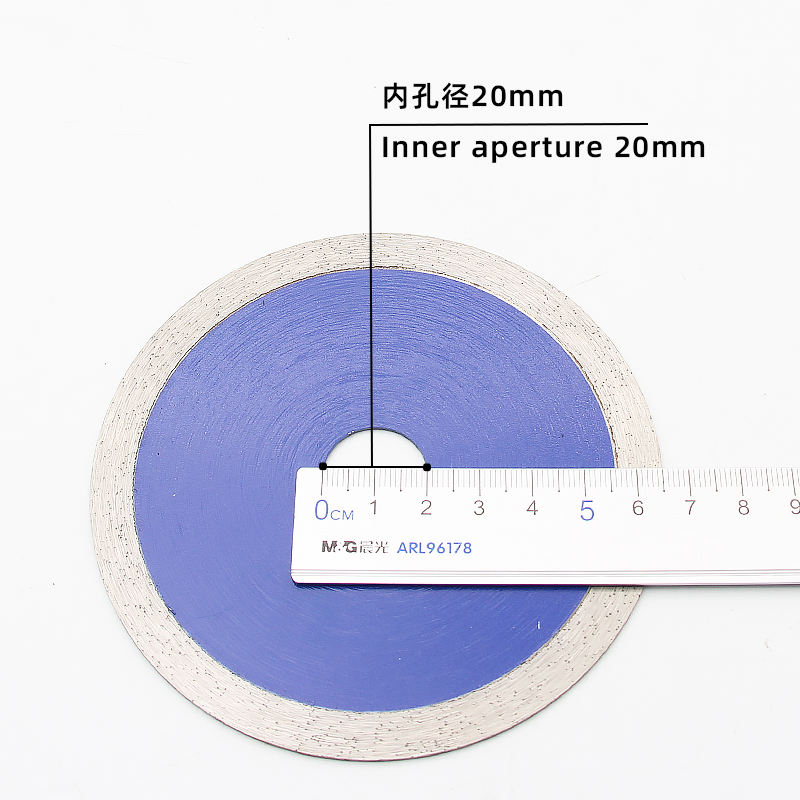

- Hole diameter: 20mm

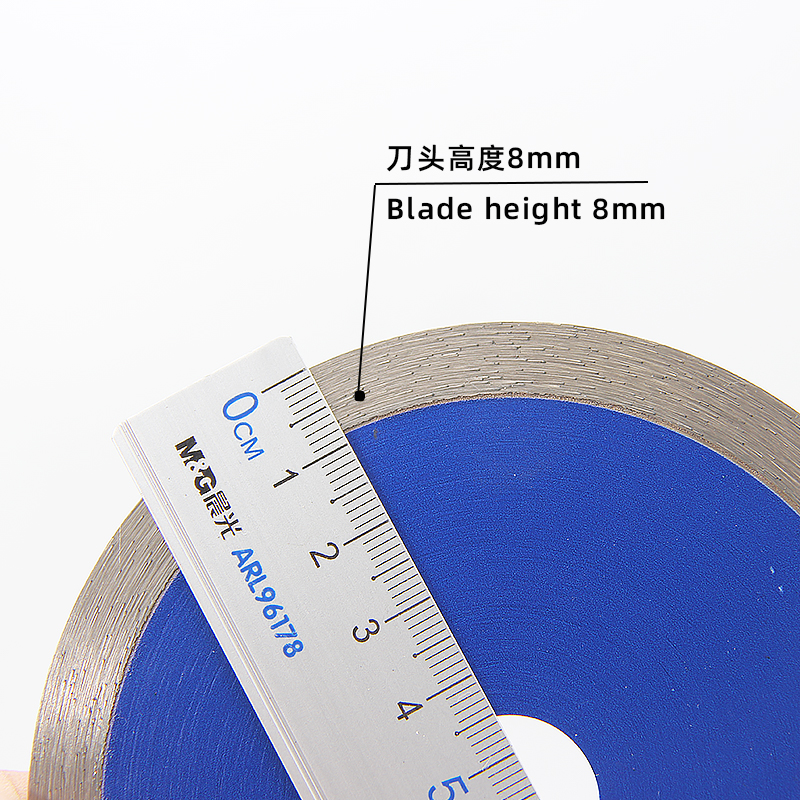

- Head height: 10mm

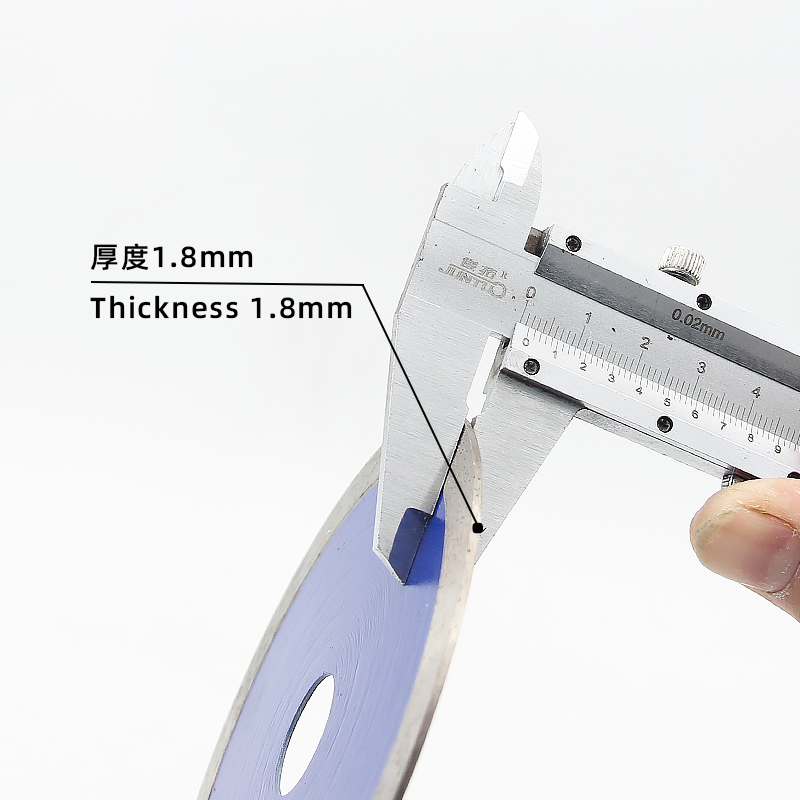

- Thickness: 1.8mm

- Place of origin: China, Shandong, Linyi

- Applications: granite, sandstone, rock slabs, marble cutting.

Product Details

110 Continuous Tooth Saw Blades (Wet & Dry Diamond) Details

Material: Diamond – the cornerstone of cutting power.

Diamond, nature’s pinnacle of hardness, provides the 110 Continuous Tooth Saw Blade with a powerful cutting edge. Its unrivaled hardness allows the saw blade to cut through a wide range of materials with the same ease as a sharp blade. Whether it’s hard granite, marble or brittle ceramic tiles, the diamond teeth quickly snap into place for an efficient cut.

At the same time, the excellent wear resistance of diamond is a major core competitiveness of this saw blade. In the long time, high intensity cutting operation, the saw blade wear degree is extremely small. Compared with ordinary saw blades, diamond saw blades can still maintain good cutting performance after many times of use, without frequent replacement of saw blades, which greatly reduces the cost of use and improves work efficiency. This is like a long-distance runner with full endurance, who always maintains a stable speed during a long race, providing long-lasting and reliable support for your cutting work.

Design: Continuous teeth – a guarantee of precise cutting

The subtle design of continuous teeth is the key to the precise and smooth cutting process of this saw blade. The consecutively arranged teeth work as a tightly knit team, with each tooth seamlessly connecting to the other as it cuts through the material, providing a constant and stable cutting force for the cutting process.

When the blade comes into contact with the material, the consecutive teeth have a larger and more even contact area with the material, avoiding fluctuations in cutting force due to intermittent tooth blades. This results in a smoother cutting action and a flatter, smoother cutting surface. When cutting ceramic tiles, it can effectively avoid chipping, falling porcelain and other problems, and the edges of the tiles cut out are neat and beautiful, almost no need for subsequent grinding treatment. When cutting stone, the continuous tooth design allows the saw blade to better cope with the hardness and toughness of the stone, cut the surface with high precision, laying a good foundation for the subsequent stone processing procedures. Whether it is a simple straight line cutting, or complex curves, shaped cutting, continuous teeth design can help the saw blade to accurately complete the task, to meet your diverse cutting needs.

Function: Wet and dry – a recipe for versatility

Wet and dry versatility gives the 110 continuous tooth saw blade a wide range of applications, enabling it to be used in a variety of different work situations.

In dry cutting mode, the blade is free from the water supply and shows great flexibility. There is no need for cumbersome water connection equipment, and the cutting operation can be started anytime and anywhere. This convenience is especially prominent in some special scenarios, such as stone quarrying or processing in the field, or in the remodeling of old buildings, the construction site is difficult to obtain water, dry cutting function allows you to quickly put to work without any delay in the construction progress. However, the dry cutting process will generate a lot of heat due to friction, which may cause the saw blade temperature to rise, affecting the cutting performance and service life.

At this point, the wet cutting function plays an important role. By connecting an external water source and spraying an appropriate amount of water on the saw blade and material during the cutting process, the dual effects of cooling and dust reduction can be realized. The cooling effect of water can effectively reduce the high temperature generated by the friction of the saw blade, prevent the saw blade from being deformed due to overheating, and protect the diamond teeth from falling off, thus prolonging the service life of the saw blade. At the same time, the water can adsorb the dust generated during the cutting process, making it settle, greatly reducing the dust content in the air, effectively improving the construction environment and protecting the health of construction workers. When cutting tiles for indoor decoration, wet cutting can avoid the pollution of the indoor environment caused by flying dust; in large stone processing workshop, the wet cutting function is to protect the air quality and production safety in the workshop.

110 Continuous Tooth Saw Blade (wet and dry diamond material) has become a high-quality tool with excellent performance and a wide range of applications in the field of cutting due to its excellent material characteristics, subtle continuous tooth design and practical wet and dry functions. Whether you are a professional construction team, a stone processing company or a DIY enthusiast, this saw blade can meet your cutting needs and bring you a perfect experience of efficiency, precision and convenience.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Testimonials

Site Search

Product Center

Testimonials

Contact Us

© 2025. All Rights Reserved.