- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+8613188737236 | Map

110 Corrugated Diamond Cutting and Grinding Blades

- Category: Customized Series, Stone Cutting Blades

- |

- Date: 01/11/2025 16:55

110 Corrugated Diamond Cutting and Grinding Blades

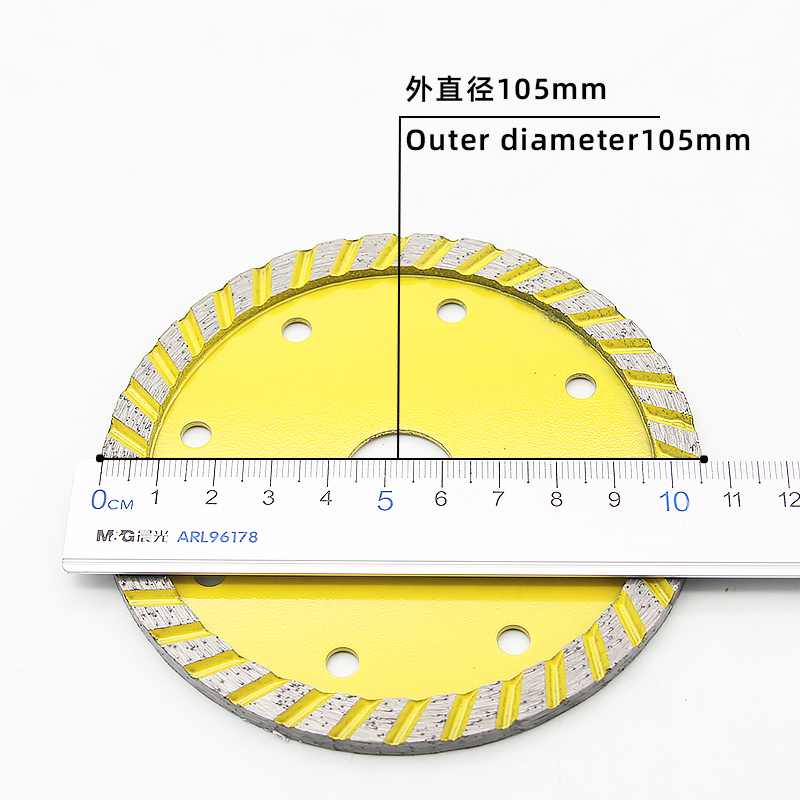

- Saw blade diameter: 110mm

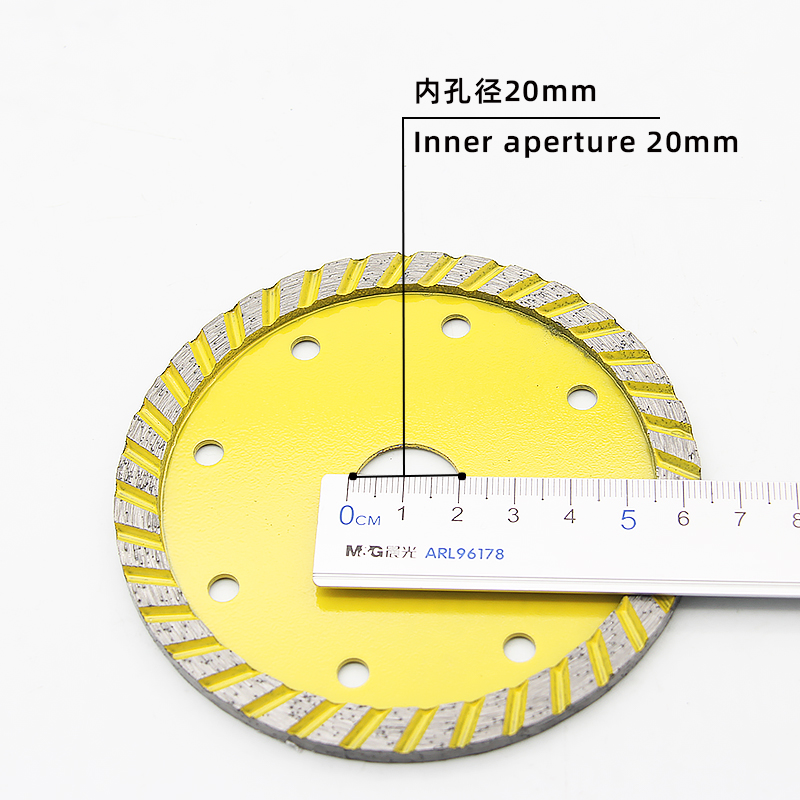

- Saw blade aperture: 20mm

- Head height: 10mm

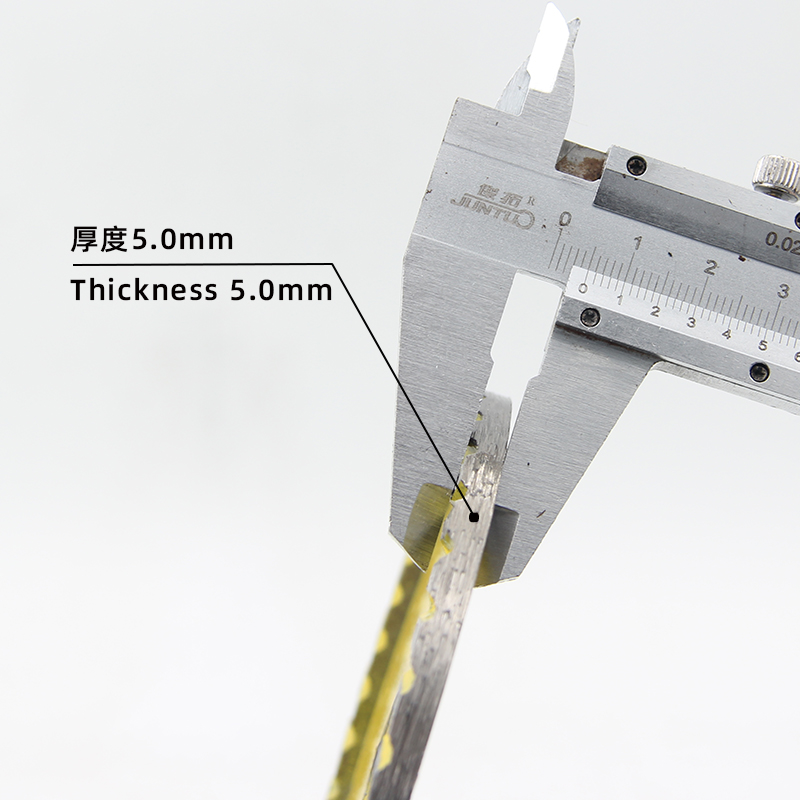

- Thickness of saw blade: 5mm

- Place of origin: China, Shandong, Linyi

- Applications: granite, marble, cutting and grinding

Product Details

110 Corrugated Tooth Diamond Cutting and Grinding Blade is a cutting tool that combines the high hardness of diamond with the design of corrugated teeth, which is commonly used for machining various hard and brittle materials. The following is a detailed analysis of 110 corrugated teeth diamond cutting and grinding wheels:

I. Structural Characteristics

Diamond particles: Diamond, as the hardest known substance, is used in the cutter head part of the cutting blade, which is able to effectively cut the object being processed during the friction cutting process.

Corrugated tooth design: Compared with the traditional straight or U teeth, the corrugated tooth design combines the advantages of continuous edge saw blades and cutter head type cutting blades, the saw teeth continuously show corrugated uniform convexity, which improves the cutting speed and increases the service life of the cutting blades.

Second, the scope of application

Stone processing: 110 corrugated teeth diamond cutting and grinding blades are especially suitable for stone processing, such as marble, granite, ceramic tiles, glazed tiles, glass tiles and so on. It can efficiently cut these hard materials while ensuring the smoothness and clarity of the cutting surface.

Concrete Processing: In the field of concrete processing, such as industrial flooring, warehouses, parking lots and other concrete floors or various aggregate hardener floor renovation treatment, 110 corrugated teeth diamond cutting and grinding blade also plays an important role. It can cut concrete quickly while reducing vibration and noise during the cutting process.

Other applications: In addition, 110 corrugated tooth diamond cutting and grinding wheels can also be used for cutting and grinding hard and brittle materials such as metal and glass. In metal processing, it can be used for cutting and chamfering metal plates, steel pipes, etc. In glass processing, it can be used for cutting and grinding glass plates, glass pipes, etc.

Third, the use of precautions

Choosing the right cutting blade: When using 110 corrugated tooth diamond cutting and grinding blades, you need to choose the right cutting blade according to the specific processing needs and material types. Different cutting blades have different cutting performance and scope of application, so choosing the right cutting blade is crucial to ensure cutting quality and efficiency.

Correct operation method: When using cutting blades, you need to follow the correct operation method. This includes ensuring that the cutting blade is firmly connected to the machine, adjusting the appropriate cutting speed and feed rate, and maintaining the proper distance between the cutting blade and the material being processed.

Safety precautions: Splashing sparks and debris may be generated during the cutting process, so proper protective equipment such as safety glasses, protective gloves, dust masks, etc. need to be worn. At the same time, it is necessary to ensure that the working area is well ventilated to minimize the accumulation of harmful substances.

To summarize, 110 corrugated tooth diamond cutting and grinding wheels are an efficient and durable cutting tool for processing a wide range of hard and brittle materials. When using it, you need to choose the right cutting blade according to the specific processing needs and material types, and follow the correct operation methods and safety protection measures.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Testimonials

WeChat Code

Site Search

Related Products

Featured Articles

© 2025. All Rights Reserved.