- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

110 Dry Slicing Bit 12 High Universal Cutting Blade

- Category: product, Stone Cutting Blades

- |

- Date: 01/18/2025 21:02

110 Dry Slicing Bit 12 High Universal Cutting Blade

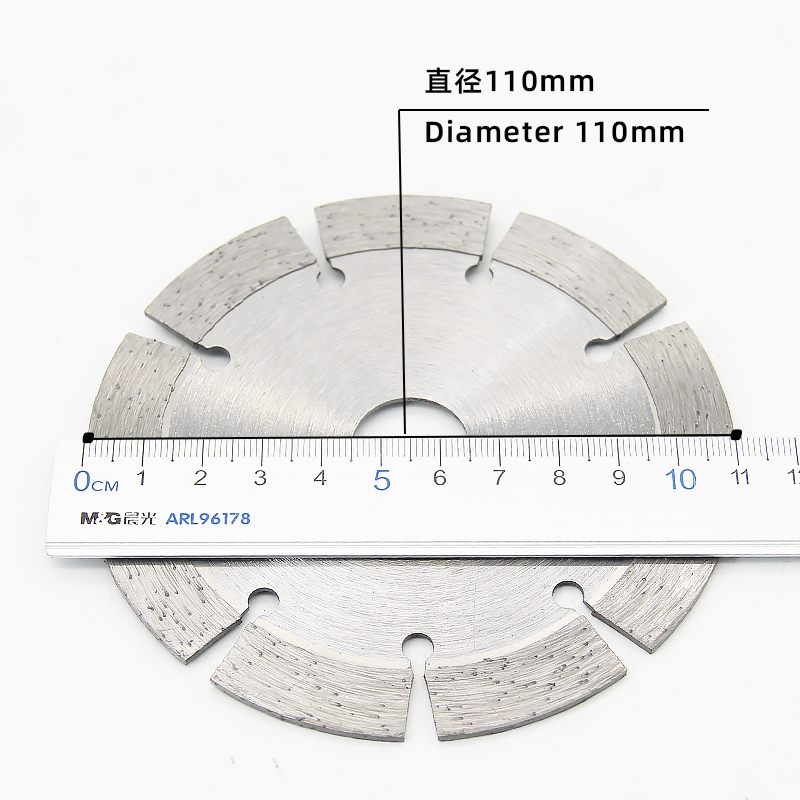

- Diameter: 110mm

- Hole diameter: 20mm

- Head height: 10mm

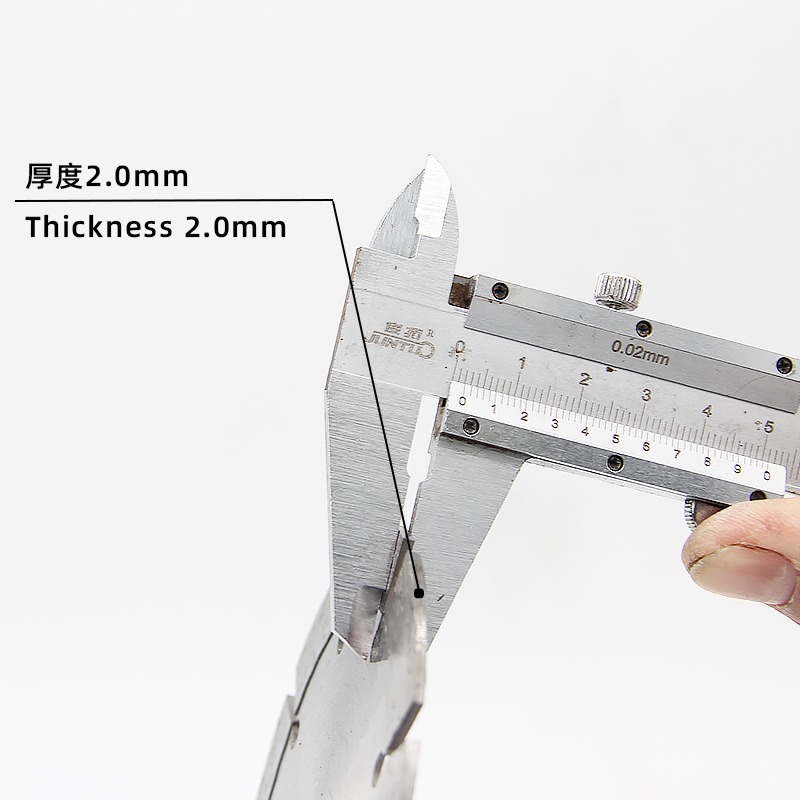

- Thickness: 1.8mm

- Thickness: 1.1mm

- Applications: granite, sandstone, rock slabs, marble cutting.

Product Details

Here is the introduction of “110 Dry Slicing Bits 12 High General Purpose Cutting Blades” diamond saw blade:

Basic parameters

Diameter: 110mm diameter size, belongs to the more common specifications, suitable for a variety of small cutting equipment, easy to operate and carry, can be used flexibly in some space-limited work scenarios.

Height of blade: The height of the blade is 12mm, a higher blade means that in the cutting process, the life of the blade is relatively long, and it can withstand more wear and tear to ensure that the cutting performance of the saw blade remains stable over a longer period of time.

Thickness: Usually the thickness of this kind of saw blade is thin, generally below 1mm, the ultra-thin design can reduce the resistance during cutting, reduce the energy loss in the cutting process, and make the cutting smoother.

Structure and Material

Substrate: generally made of high-strength steel, with good toughness and rigidity, can provide solid support for the cutter head, to ensure that the blade will not be deformed or ruptured in the high-speed rotation and cutting process, to ensure the stability and safety of cutting.

Blade head: The blade head contains diamond particles, which is the key to the efficient cutting of the saw blade. As the hardest substance in nature, diamond has extremely high hardness and wear resistance, and can easily grind all kinds of hard and brittle materials during cutting. The diamond particles are wrapped by a metal carcass, which serves to hold the diamond particles in place and gradually wears down during the cutting process, exposing new diamond particles and maintaining the sharpness of the saw blade.

Manufacturing process

Sintering process: Cold press sintering or hot press sintering may be used. Cold press sintering is to mix the diamond particles with metal powder, then mold them by cold pressing, and then sinter them under high temperature, so that the diamond particles and metal carcass are closely combined; hot press sintering is to press and sinter them under higher temperature and pressure, so that it can obtain higher bonding strength and more uniform distribution of diamond, and thus improve the overall performance of the saw blades.

Welding process: High-frequency welding, laser welding or brazing in the welding process may also be utilized. High-frequency welding through high-temperature melting medium will cutter head and the substrate welded together to form a strong bond; laser welding using high-temperature laser beams will cutter head and the substrate contact edge melting, the formation of metallurgical bonding, with higher strength and precision; brazing is a flame spraying method will be brazing alloy plating in the tool steel substrate, and then the diamond fabricated in the solder level, and then at high temperatures, protective gas inductively brazed to Realize the combination of diamond and steel substrate.

Performance Characteristics

High cutting efficiency: the high hardness of diamond enables the saw blade to cut into various hard and brittle materials such as stone, ceramics, concrete, etc. The cutting speed is greatly increased compared with ordinary cutting blades, which can effectively shorten the working time and improve the working efficiency.

Strong durability: Due to the extremely high wear resistance of the diamond particles in the cutter head, as well as the reasonable design and manufacturing process of the cutter head, this saw blade has a long service life, which reduces the frequency of replacing the saw blade and lowers the cost of use.

Good versatility: Being called a general-purpose cutting blade means that it can be suitable for cutting many different types of hard and brittle materials, whether it is stone such as marble and granite, ceramic materials such as tiles and ceramic boards, or concrete products, all of them can show good cutting performance and have a wide range of applications.

Excellent dry-cutting performance: It is specially labeled as dry-cutting slice, indicating that it can maintain good cutting effect and stability under dry-cutting conditions. This is due to its unique formula and design, which can effectively dissipate heat without the use of coolant, reducing friction and heat accumulation during the cutting process, avoiding damage to the saw blade due to overheating, and at the same time ensuring the quality of the cutting surface.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Testimonials

Site Search

Product Center

Testimonials

Contact Us

© 2025. All Rights Reserved.