- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

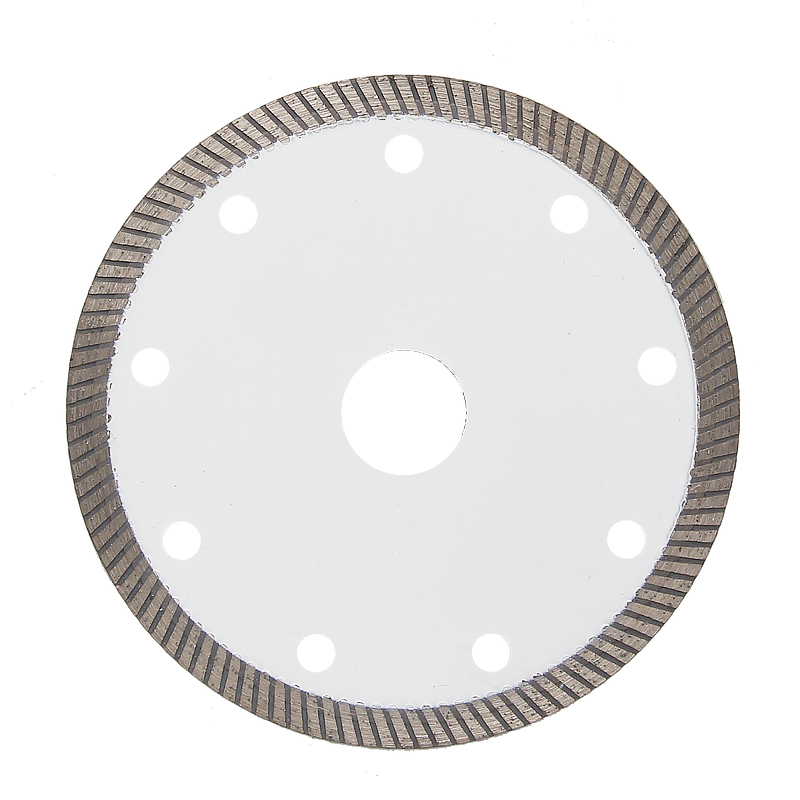

110 Small corrugated tile cutting disk

- Category: Products, Tile Cutting Blade

- |

- Date: 01/19/2025 20:09

Introduction of 110 small corrugated tile cutting disk Its production process is the hot pressing process Made of diamond material

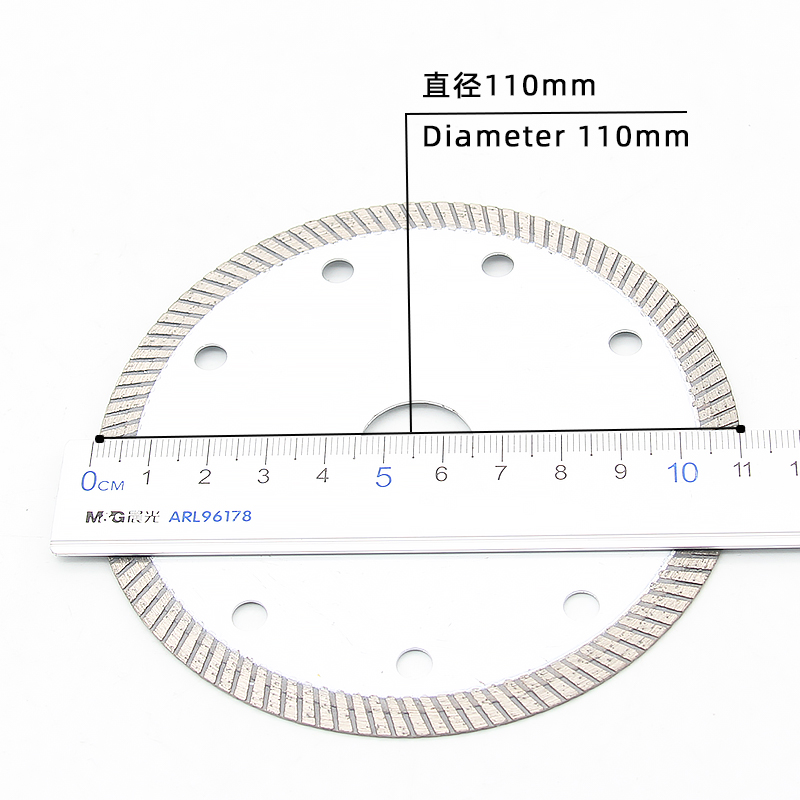

- Diameter: 110mm

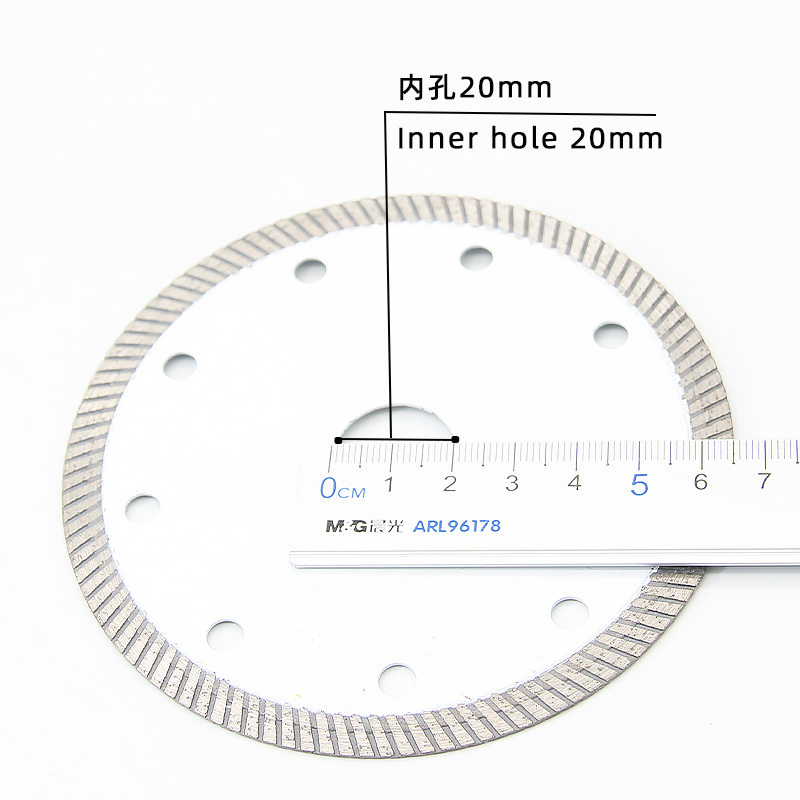

- Hole diameter: 20mm

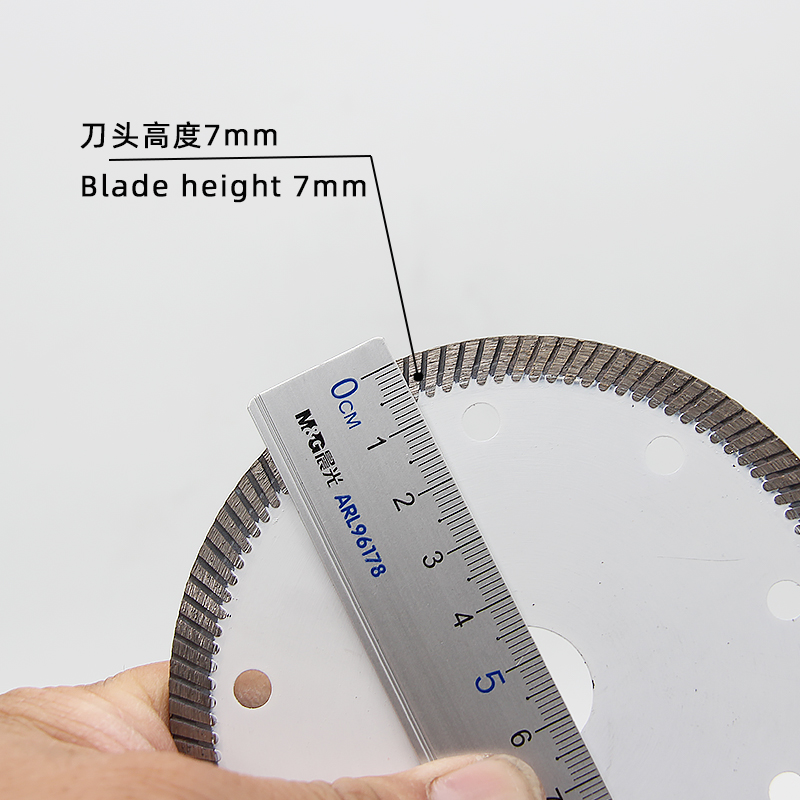

- Head height: 7mm

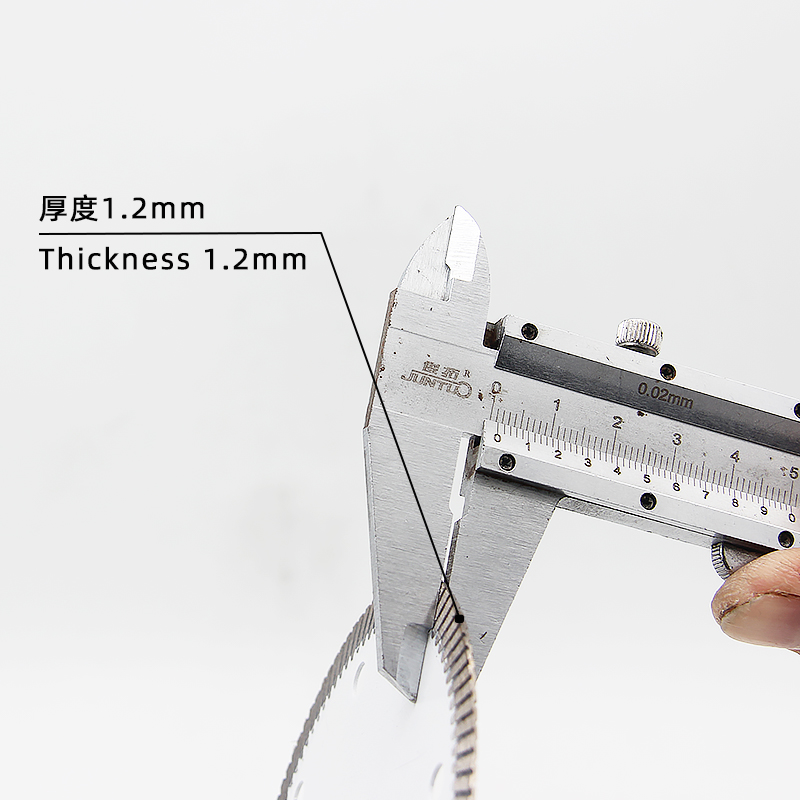

- Thickness: 1.2mm

- Place of origin: China, Shandong, Linyi

- Applications: ceramics, tiles, rock slabs, microcrystalline stone cutting.

Product Details

110 Small Corrugated Tile Cutting Disc Introduction

In the field of tile cutting, the 110 Small Corrugated Tile Cutting Disc has won the favor of the majority of users due to its high efficiency, precision and durability. This cutting disk adopts advanced hot pressing process and diamond as the main material to ensure its excellent performance in the cutting process.

I. Product Features

Precise Cutting: 110 small corrugated tile cutting disk is designed with cutting precision and stability in mind. Its unique corrugated design makes the cutting surface more flat and reduces vibration and deviation during the cutting process, thus ensuring the precision of cutting.

High efficiency and durability: Diamond, as the main material of the cutting disc, significantly improves the service life of the disc with its high hardness and wear resistance. Meanwhile, the application of the hot pressing process makes the diamond particles more tightly bonded together, which further enhances the durability of the cutting disk.

Wide applicability: this cutting disc is suitable for cutting various tiles, glass tiles, marble and other hard materials. Its corrugated design not only improves the cutting efficiency, but also reduces the noise and dust during the cutting process, providing users with a more comfortable working environment.

Second, the production process

The production process of 110 small corrugated tile cutting disk adopts advanced hot pressing technology. First of all, the diamond particles are mixed with the appropriate amount of binder and then filled into the mold. Then, under the condition of high temperature and high pressure, the mold is hot-pressed, so that the diamond particles and the binder are tightly combined to form a strong cutting disc. During this process, parameters such as hot pressing temperature, pressure and time need to be strictly controlled to ensure the quality and performance of the cutting disk.

Third, diamond material

As the main material of cutting disk, diamond has extremely high hardness and wear resistance. In the cutting process, diamond particles can quickly cut into the material inside, reducing cutting resistance and energy consumption. At the same time, the sharpness of diamond particles is maintained for a long time, which can significantly improve the cutting efficiency and precision. In addition, diamond also has excellent chemical and thermal stability, and can maintain stable performance in a variety of harsh working environments.

Fourth, the use and maintenance

When using 110 small corrugated tile cutting disk, users need to pay attention to the following points:

Choose the right cutting speed: too fast or too slow cutting speed will affect the cutting effect. Users should choose the appropriate cutting speed according to the hardness and thickness of the material.

Keep the cutting disk clean: the dust and debris generated during the cutting process will affect the cutting effect of the cutting disk. Therefore, users need to clean the dust and debris on the surface of the cutting disk regularly.

Regularly replace the cutting disk: With the increase of using time, the sharpness and durability of the cutting disk will gradually decrease. Users should regularly replace the cutting disk according to the actual situation to ensure the cutting effect.

To summarize, 110 small corrugated tile cutting disc has become a leader in the tile cutting field with its precise cutting, high efficiency and durability, and wide applicability. Its advanced hot pressing process and the application of diamond material provide users with a more efficient and precise cutting experience.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Testimonials

Site Search

Product Center

Testimonials

Contact Us

© 2025. All Rights Reserved.