- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

125 Continuous Tooth Transparent Red Customized in Small Quantities

- Category: Customized Series, product, Stone Cutting Blades

- |

- Date: 01/31/2025 18:31

In the industrial cutting field, unique and personalized cutting tools can bring more value to production. Our 125 - continuous - tooth transparent red cutting disc now supports small - batch customization, aiming to meet diverse needs.

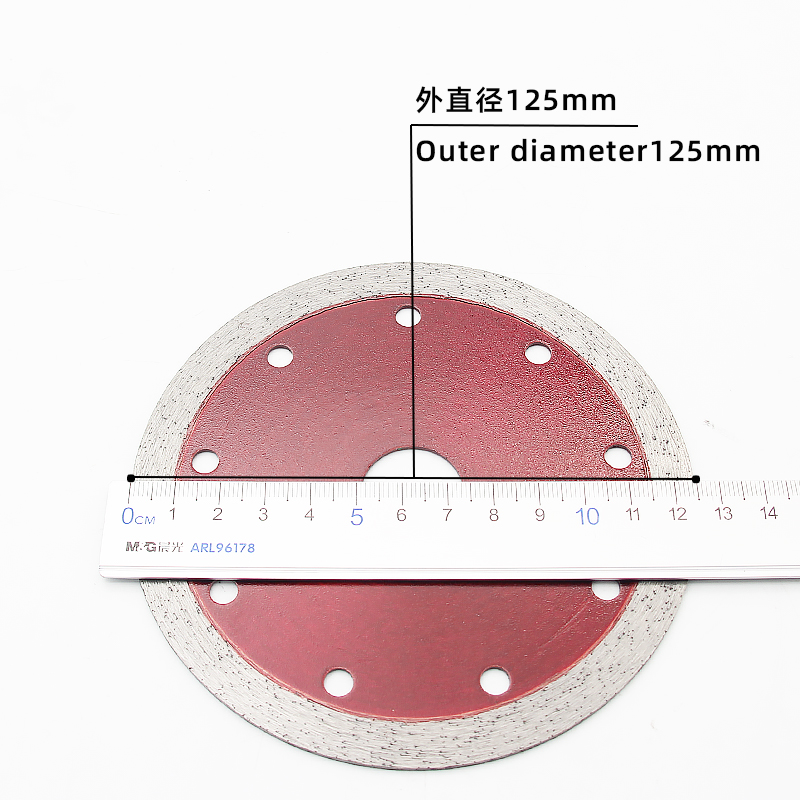

- Diameter: 125mm

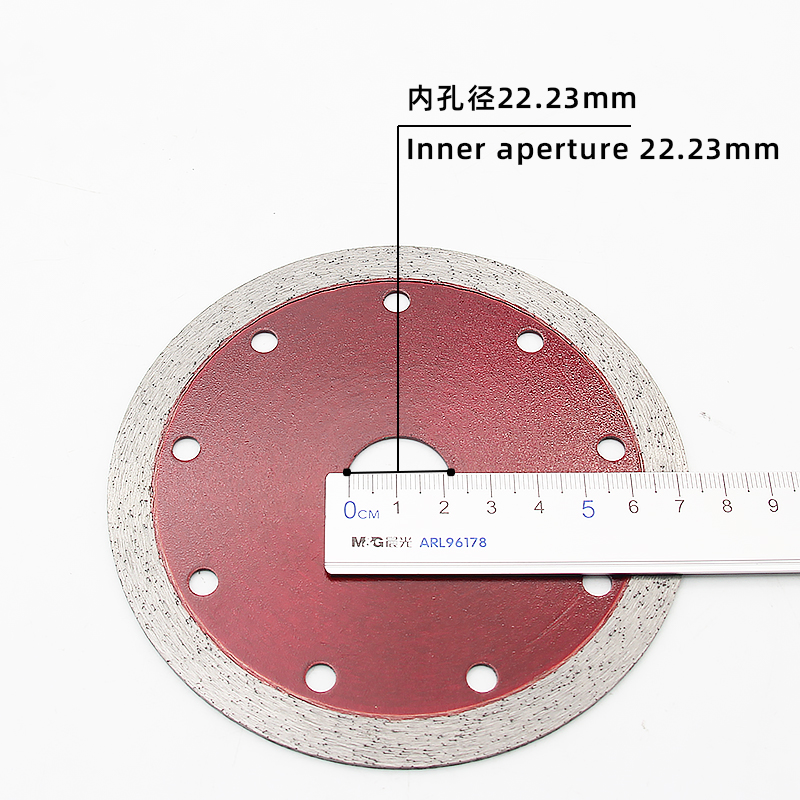

- Hole diameter: 22.23mm

- Head height: 10mm

- Thickness: 1.8mm

- Place of origin: China, Shandong, Linyi

- Applications: granite, sandstone, rock slabs, marble cutting.

Product Details

Introduction to Small – Batch Customization of 125 Continuous Tooth Transparent Red Cutting Disc

In the industrial cutting field, unique and personalized cutting tools can bring more value to production. Our 125 – continuous – tooth transparent red cutting disc now supports small – batch customization, aiming to meet diverse needs.

Customization Advantage: Small – Batch Flexibility

We understand that different projects have different requirements. Therefore, we offer small – batch customization services. Whether you need a small quantity for special experiments, trial production, or a customized order for a unique project, we can meet your demands. This flexibility allows you to test the performance of the cutting disc without large – scale investment.

Distinctive Feature: Transparent Red Appearance

The transparent red color of this cutting disc is not only eye – catching but also has practical significance. It provides a unique visual effect during the cutting process, making it easier to observe the cutting situation. This feature is especially useful in some precision – cutting scenarios where real – time monitoring is required.

Advanced Process and Quality Assurance

The hot – pressing production process we adopt is a major highlight of this cutting disc. During the hot – pressing process, the high – temperature and high – pressure environment promotes the close integration of diamond abrasives and metal binders at the molecular level. This integration method greatly enhances the bonding strength between the two, ensuring that the cutting disc has high wear resistance and is not easily worn during long – term cutting operations. At the same time, the tight structure makes the cutting disc more stable during cutting, and the cutting efficiency far exceeds that of products made by ordinary processes.

The diamond material itself has ultra – high hardness and excellent wear resistance. Coupled with the advanced hot – pressing process, the cutting disc can precisely and efficiently handle various hard materials. The loss during the cutting process is minimized, and the service life of the product is extended.

Precise Specifications for Wide Applicability

In terms of specifications, the cutting disc has a diameter of 125mm and an inner hole of 22.23mm. These dimensions are suitable for most common cutting equipment on the market, ensuring convenient installation and use. Whether it is used in construction, metal processing, or stone processing, it is a reliable choice.

Dual – Use Function for Different Environments

This cutting disc also has a unique wet – and – dry dual – use cutting function. When dry – cutting, it can meet the needs of special working environments where water cannot be used. The cutting efficiency is high, and the operation is convenient.

When cutting with water added, it can effectively reduce the temperature during the cutting process and reduce dust generation. This not only protects the working environment but also extends the service life of the cutting disc. At the same time, the flatness and smoothness of the cutting surface are improved, ensuring better cutting quality.

As a manufacturer with advanced production equipment and a professional technical team, we strictly control every production process to ensure the stable and reliable quality of customized products. Choosing our small – batch customized 125 – continuous – tooth transparent red cutting disc means choosing a customized, efficient, and high – quality cutting solution.

This product can be customized and we also have a big red product released.125 Continuous Tooth Wet And Dry Cutting Blades In addition, I also produce 110 continuous tooth cutting discs. 110 Continuous Tooth Saw Blades For Wet And Dry Cutting

Zhanyuetool

Shandong Zhan Yue Tools Co.

Testimonials

WeChat Code

Site Search

Related Products

Featured Articles

© 2025. All Rights Reserved.