- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

125 Stone Cutting Blade Corrugated Tooth Type

- Category: Customized Series, Products, Stone Cutting Blades

- |

- Date: 01/21/2025 19:39

125 Stone Cutting Blade Corrugated Tooth Type Hot Press Diamond Saw Blade

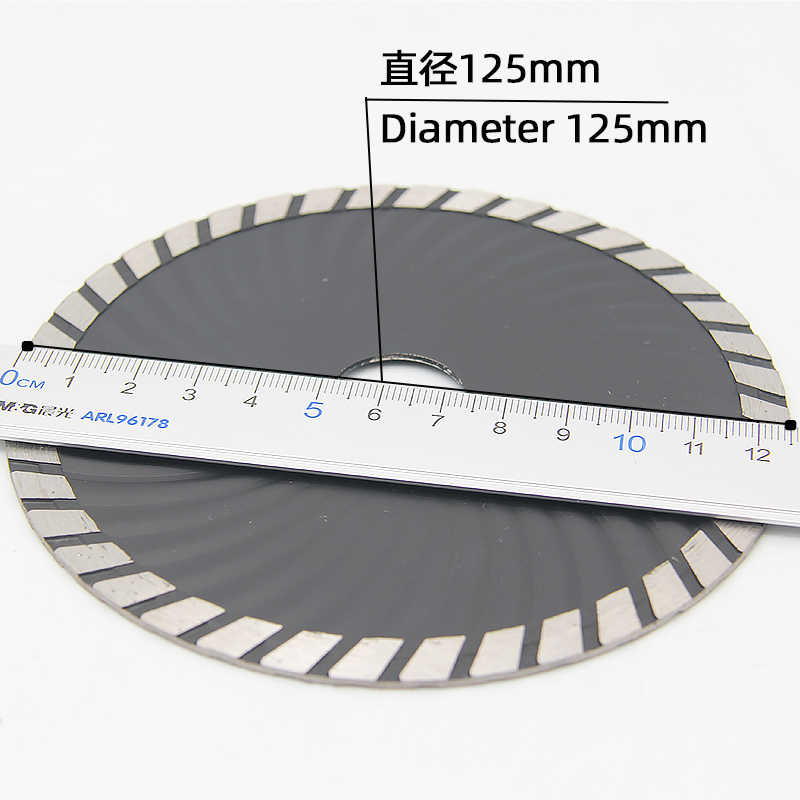

- Diameter: 125mm

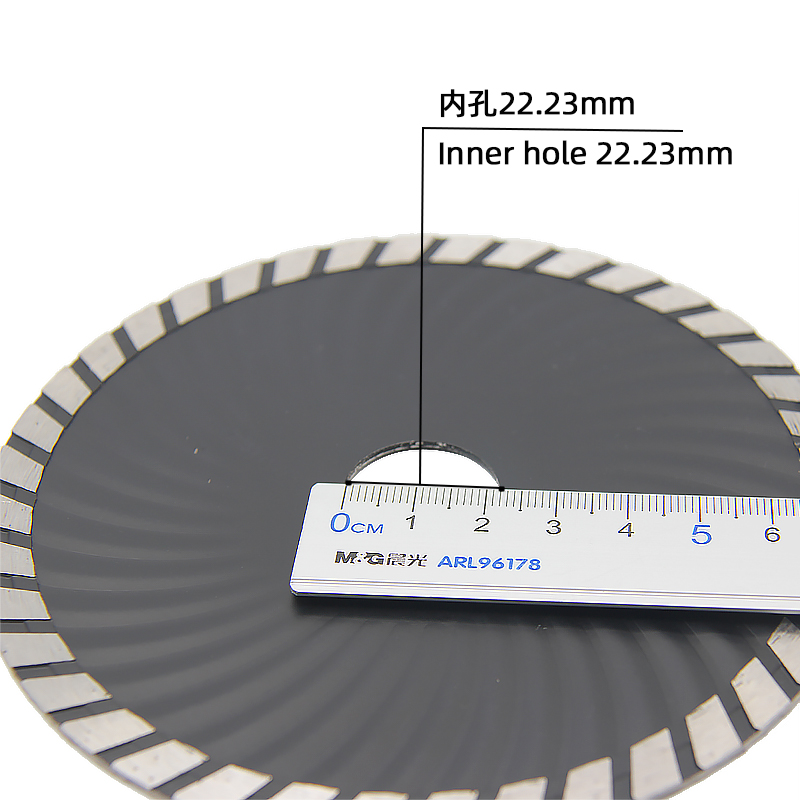

- Hole diameter: 22.23mm

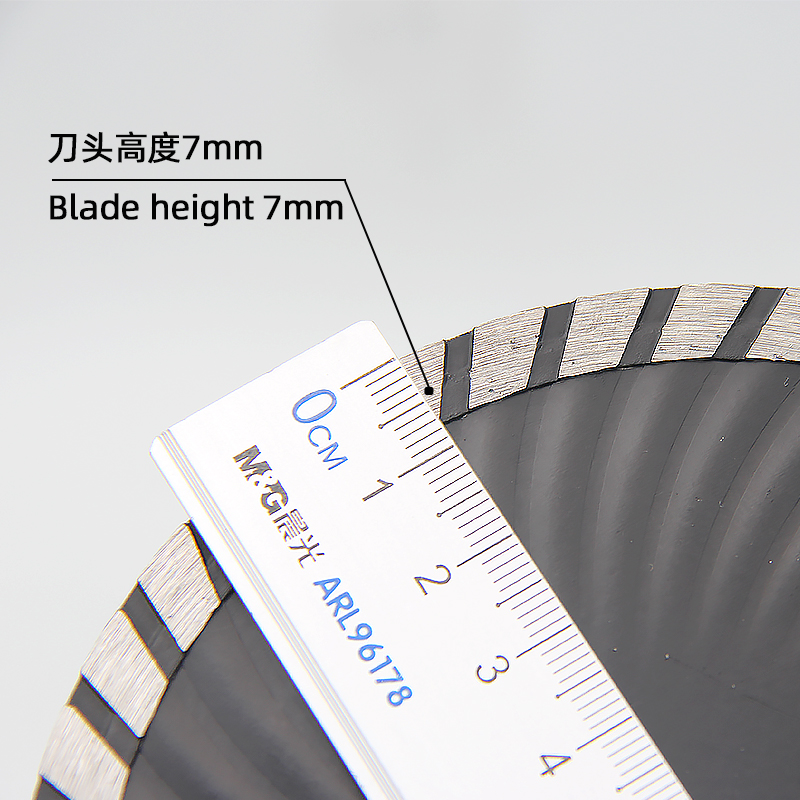

- Head height: 10mm

- Thickness: 1.8mm

- Place of origin: China, Shandong, Linyi

- Applications: granite, sandstone, rock slabs, marble cutting.

Product Details

125 Stone Cutting Blade with Corrugated Tooth Type, Hot – Pressed Diamond Saw Blade: Made in China, Customizable

In the field of stone processing, the performance of cutting tools directly affects processing efficiency and product quality. Today, we would like to introduce you to an outstanding cutting tool – the 125 stone cutting blade with corrugated tooth type, hot – pressed diamond saw blade. It showcases the exquisite craftsmanship of Chinese manufacturing and also offers customization services to meet the diverse needs of different customers.

I. Excellent Design and Craftsmanship

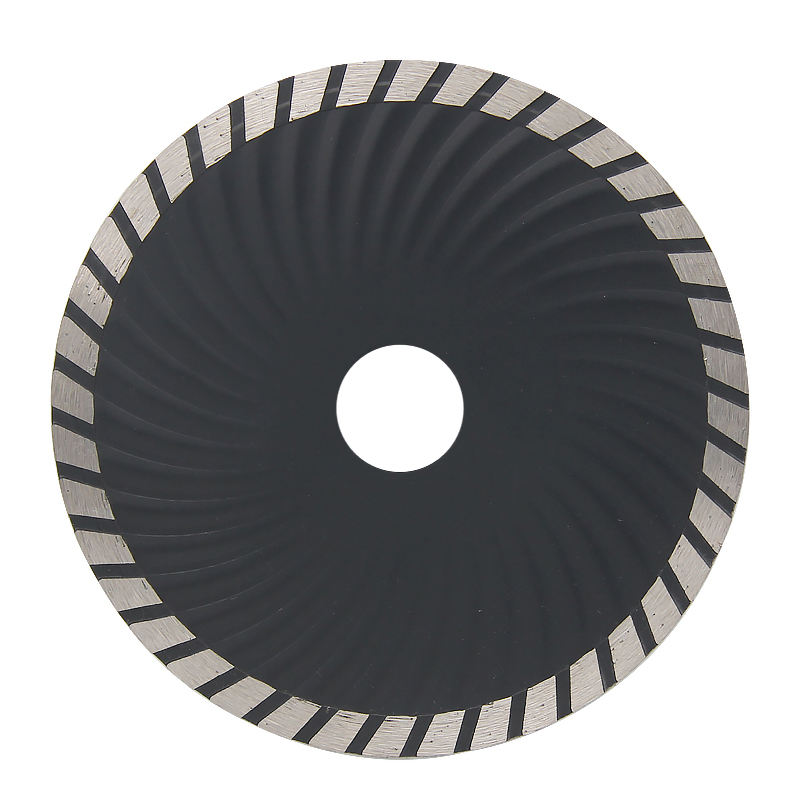

(1) Corrugated Tooth Design

This saw blade features a unique corrugated tooth design, which has significant advantages over the traditional flat – tooth design. When cutting, the corrugated teeth can form multiple contact points with the stone surface, dispersing the cutting force and reducing the resistance during the cutting process. This not only makes the cutting process smoother but also effectively reduces the wear of the saw blade, extending its service life. Moreover, the corrugated tooth design can generate continuous cutting actions during cutting, resulting in a faster cutting speed and greatly improving the efficiency of stone processing.

(2) Hot – Pressing Process

The hot – pressing process is the key to ensuring the quality of this saw blade. During the hot – pressing process, diamond particles and the saw blade matrix are perfectly combined under high – temperature and high – pressure conditions. This combination method firmly inlays the diamond particles on the saw blade, enabling it to withstand high – intensity cutting work. At the same time, the hot – pressing process can ensure the uniform overall structure of the saw blade, providing higher stability. It is not prone to deformation during high – speed rotation cutting, guaranteeing the accuracy and quality of cutting.

II. Quality Assurance of Chinese Manufacturing

Chinese manufacturing is renowned worldwide for its high quality and cost – effectiveness. This 125 stone cutting blade with corrugated tooth type, hot – pressed diamond saw blade is a powerful testament to China’s manufacturing strength.

(1) Stringent Quality Control

From the procurement of raw materials to the ex – factory of finished products, every link follows strict quality standards. High – quality diamond particles are carefully selected, which possess high hardness and wear resistance, laying a solid foundation for the cutting performance of the saw blade. At the same time, strict control is exerted over the material and manufacturing process of the saw blade matrix to ensure that its strength and toughness can meet the needs of different stone cutting. During the production process, multiple quality inspection procedures are set up to test key indicators such as the dimensional accuracy, hardness, and flatness of the saw blade. Only products that fully meet the standards can enter the market.

(2) Advanced Production Equipment and Technology

Chinese manufacturers are equipped with advanced production equipment and technology. These devices can precisely control the parameters of the hot – pressing process, ensuring the quality stability of each saw blade. Meanwhile, new technologies are continuously introduced and developed to improve the performance of products. For example, by optimizing the distribution and concentration of diamond particles, the cutting efficiency and service life of the saw blade are further enhanced. In addition, manufacturers attach great importance to talent cultivation and have a professional technical team that can continuously innovate and improve the production process to adapt to market demands.

III. Customization Services to Meet Individual Needs

We are well aware that different customers have different requirements in stone cutting, so we specifically offer customization services.

(1) Customization of Cutting Performance

Based on the type and hardness of the stone cut by the customer, we can customize saw blades with different diamond grain sizes and concentrations. For granite with high hardness, the concentration of diamond can be increased to improve the wear resistance of the saw blade. For marble with a softer texture, finer – grained diamond can be selected to obtain a smoother cutting surface.

(2) Customization of Size Specifications

In addition to the standard 125 specification, we can also customize saw blades with different diameters, thicknesses, and hole diameters according to the customer’s cutting equipment and actual needs. Whether it is a small – scale stone processing workshop or a large – scale stone production line, they can find a saw blade suitable for their equipment.

(3) Customization of Appearance and Logo

To help customers build their brand image, we also provide customization services for appearance and logo. Customers can have their brand logo, contact information, and other information customized on the saw blade, enhancing brand recognition.

In conclusion, the 125 stone cutting blade with corrugated tooth type, hot – pressed diamond saw blade, with its excellent design and craftsmanship, quality assurance of Chinese manufacturing, and personalized customization services, is an ideal choice for the stone processing industry. Whether you are a stone processing enterprise or a professional engaged in related projects, we believe this saw blade can bring you an efficient and high – quality cutting experience. Choose us, and you choose professionalism and quality. Let’s work hand in hand to boost your stone processing business!

More product customization can also be viewed in our product listing Customized series

Zhanyuetool

Shandong Zhan Yue Tools Co.

Testimonials

WeChat Code

Site Search

Related Products

Featured Articles

© 2025. All Rights Reserved.