- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

125 stone diamond saw blades small batch production

- Category: Customized Series, Products, Stone Cutting Blades

- |

- Date: 01/23/2025 22:16

125-cut diamond saw blades with corrugated teeth for stone cutting, produced in small batches by a Chinese manufacturer.

- Diameter: 125mm

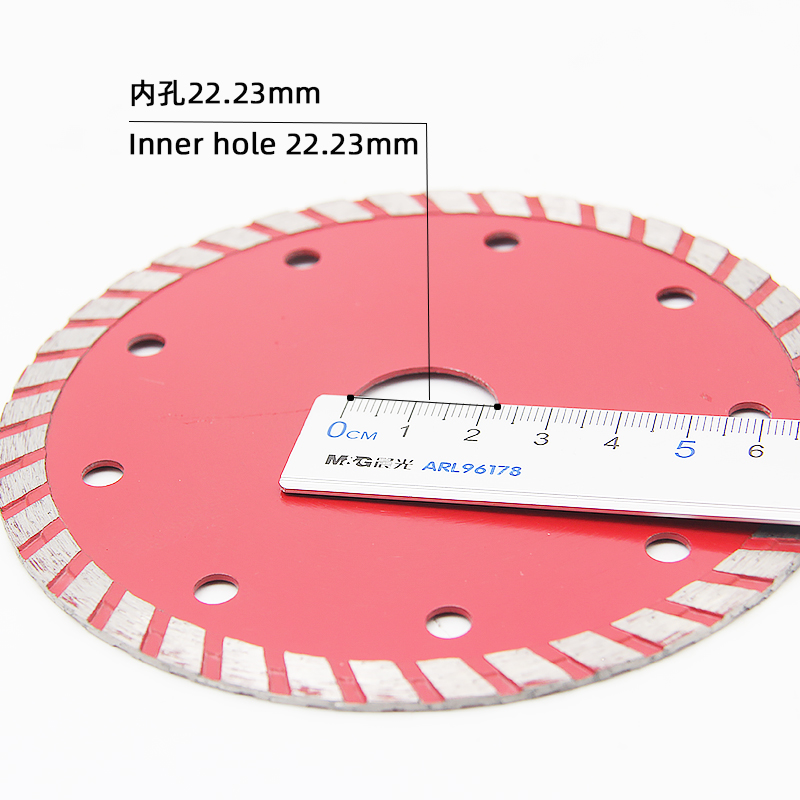

- Hole diameter: 22.23mm

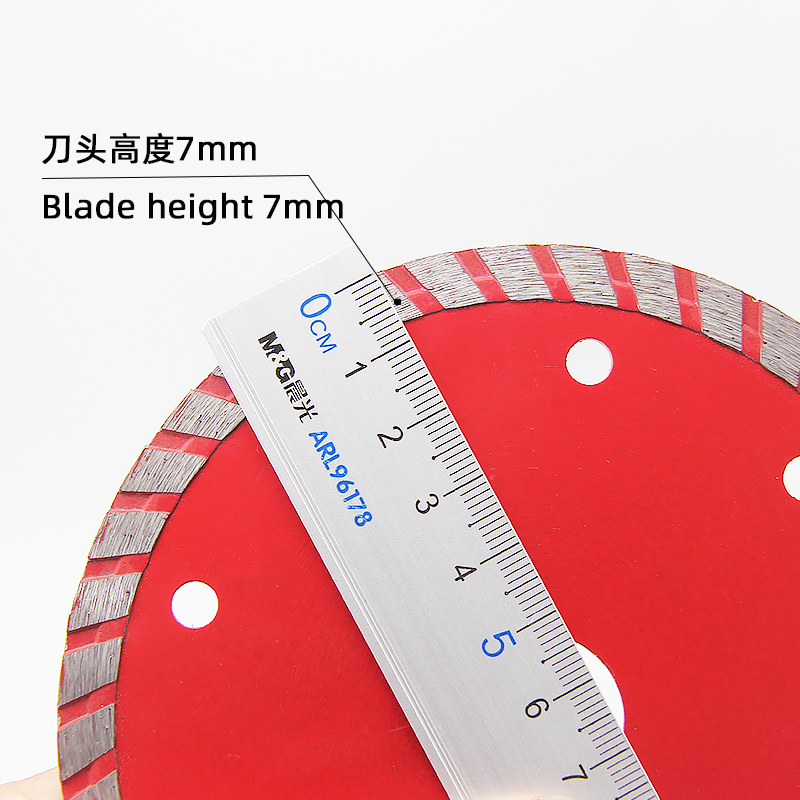

- Head height: 10mm

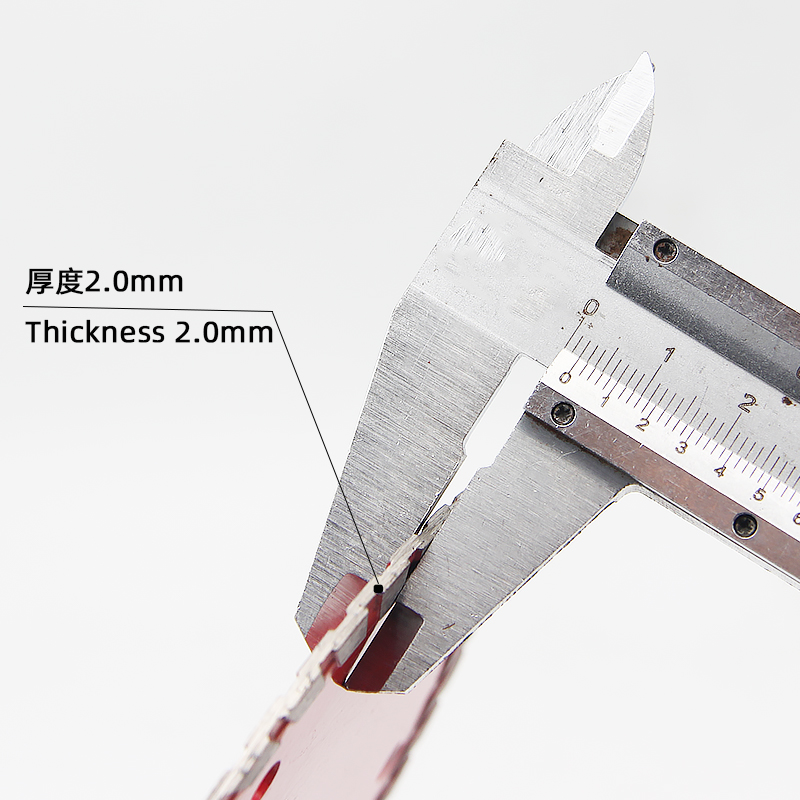

- Thickness: 1.8mm

- Place of origin: China, Shandong, Linyi

- Applications: granite, sandstone, rock slabs, marble cutting.

Product Details

Product Basic Information

- Model: According to the naming rules of Shandong Zhanyue Tools, it is a 125 – specification product in a certain series.

- Size: With a diameter of 125mm, it is suitable for common small – scale stone cutting equipment and is a commonly used specification for stone cutting.

- Tooth Shape: It adopts a corrugated tooth design. This tooth shape can increase the contact area between the saw blade and the stone, making the cutting process more stable, reducing vibration and noise. At the same time, the special shape is conducive to chip removal, which can timely discharge the stone chips generated during cutting, avoid chip accumulation, and improve the cutting efficiency and the service life of the saw blade.

Manufacturer

- Shandong Zhanyue Tools: Located in Shandong, it focuses on the research, development, and production of various tools and has made remarkable achievements in the field of diamond saw blades. The manufacturer has strong technical strength and advanced equipment, and has the flexible ability for small – batch production, which can fully meet the diverse needs of different customers. Whether customers have special customization requirements for products or only need to purchase a small quantity, Shandong Zhanyue Tools can fully cooperate and provide high – quality products and services.

Product Features

- High Sharpness: High – quality diamond particles are selected as the cutting material. These diamond particles have extremely high hardness and wear resistance, and can quickly cut into the stone to achieve efficient cutting. Whether it is hard granite or soft marble, it can easily handle them and maintain good sharpness.

- Strong Durability: Through advanced production processes, the diamond particles are firmly bonded to the saw blade substrate to ensure that the particles are not easy to fall off during long – term cutting. The saw blade substrate is made of high – strength metal materials, with excellent toughness and anti – deformation ability, which can withstand the huge pressure during cutting and effectively extend the service life of the saw blade.

- Good Cutting Quality: Thanks to the corrugated tooth design and high – precision manufacturing, when cutting stones, the cutting surface can be guaranteed to be flat and smooth, reducing cutting errors and improving the processing quality of stones. This is crucial for projects with high precision requirements, such as stone carving and decoration.

The same product has a:125 Stone Cutting Blade Corrugated Tooth Type

Tags: 125mm

Zhanyuetool

Shandong Zhan Yue Tools Co.

WeChat Code

Site Search

Related Products

Featured Articles

© 2025. All Rights Reserved.