- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

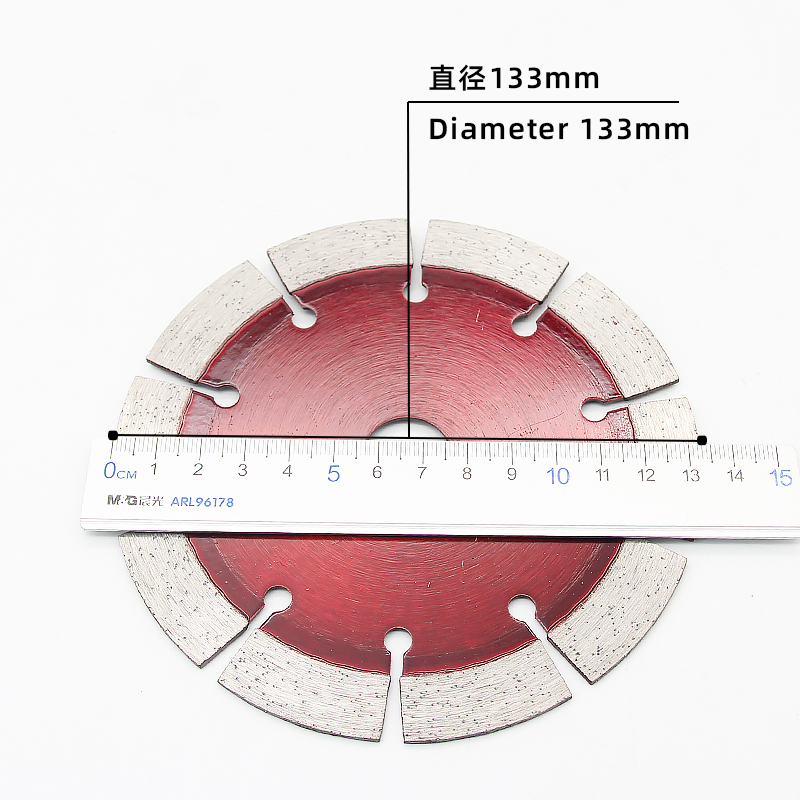

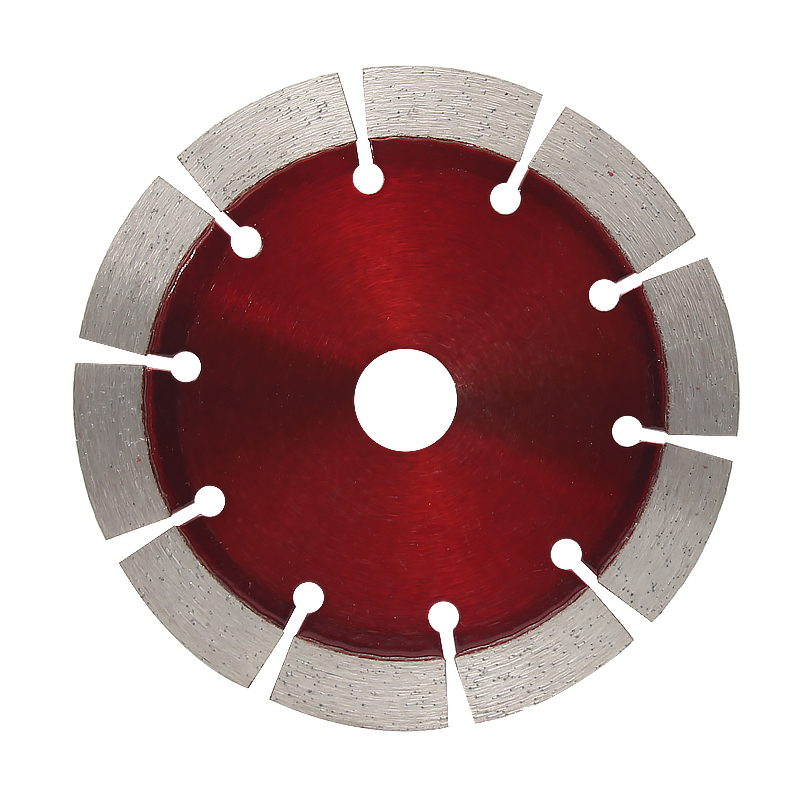

133 Dry Slicing Bit 15 High Universal Cutting Blade

- Category: Customized Series, product, Stone Cutting Blades

- |

- Date: 02/01/2025 12:06

High - Efficiency Cutting Tool: 133 Dry - Cutting Segment with 15 - High Universal Cutting Disc

- Diameter: 133mm

- Hole diameter: 20mm

- Head height: 15mm

- Thickness: 2.0mm

- Place of origin: China, Shandong, Linyi

- Applications: granite, sandstone, rock slabs, marble cutting.

Product Details

High – Efficiency Cutting Tool: 133 Dry – Cutting Segment with 15 – High Universal Cutting Disc

In the cutting field, a cutting disc with excellent performance can greatly improve work efficiency and cutting quality. Today, I would like to introduce you to our factory’s star product – the 133 dry – cutting segment with 15 – high universal cutting disc.The 110 size dry slices are also very popular compared to similar products of the same size You can see the 110 size dry slices below:110 Dry Slicing Bit 12 High Universal Cutting Blade

Product Basic Parameters

This cutting disc has a diameter of 133mm, a bore diameter of 20mm, and a segment height of up to 15mm. Don’t underestimate these numbers; they determine the performance of the cutting disc in actual use. The appropriate diameter and bore diameter ensure that the cutting disc can be perfectly adapted to most cutting equipment on the market, with extremely strong versatility. And the 15mm segment height provides the cutting disc with more lasting cutting ability, reduces the trouble of frequent cutting disc replacement, and improves work efficiency.

Hot – Pressing Production Process

Our 133 dry – cutting disc adopts an advanced hot – pressing production process. This process makes the bond between the segment and the substrate closer and more secure, effectively avoiding the risk of segment detachment during high – speed cutting and greatly enhancing the safety and stability of the cutting disc. At the same time, the hot – pressing process makes the internal structure of the cutting disc more uniform, ensuring the smoothness of the cutting process. Whether cutting stone, metal, or other materials, a smooth and flat cutting surface can be achieved, reducing subsequent processing procedures.

Adaptability to Multiple Cutting Scenarios

Granite Cutting

Granite is hard in texture and high in density, making it more difficult to cut. Our 133 dry – cutting disc, with its sharp segments and stable structure, can efficiently cut into granite, maintain a stable cutting speed during the cutting process, reduce 卡顿现象 (卡顿现象 can be translated as “jamming phenomena” or “sticking phenomena”), and the cutting surface is fine and flat, reducing the workload of subsequent polishing.

Marble Cutting

Marble is relatively brittle in texture and has extremely high requirements for the smoothness of the cutting disc. With the support of the hot – pressing process, the internal structure of this cutting disc is uniform, and the vibration during cutting is minimal, minimizing the problems of edge chipping and fragmentation of marble during the cutting process and being able to perfectly present the natural texture and texture of marble.

Concrete and Red Brick Cutting

Concrete and red bricks contain hard particles such as sand and gravel, which pose a great test to the wear resistance of the cutting disc. The high – hardness segments and firm bonding process of the 133 dry – cutting disc enable it to exhibit strong wear resistance when cutting concrete and red bricks. It is not easy to wear even after long – term use, greatly extending the service life and reducing the cutting cost.Model 133 dryer sheets may not be as widely used as Model 125 dryer sheets. If you have a need for Model 125, you can check out our Model 125 dryer sheets. :125 General Purpose Dry Slicing 10-tooth

Cost – Advantage

From the perspective of long – term use cost, this 133 dry – cutting disc has obvious advantages. Due to its excellent wear resistance and long service life, in frequent cutting operations, the replacement frequency is much lower than that of ordinary cutting discs, reducing the procurement frequency and inventory cost. At the same time, the high – efficiency cutting efficiency means that more cutting tasks can be completed per unit time, improving the utilization rate of equipment and further diluting the equipment use cost and labor cost, bringing tangible economic benefits to enterprises.

Real User Feedback

Many users have highly praised this 133 dry – cutting disc after use. The owner of a stone processing factory said, “Previously, when cutting granite, not only was the efficiency low, but the cutting surface was also rough. Since using this cutting disc, the efficiency has increased by nearly 30%, and the cutting surface is smooth. The polishing process has become much easier, and the production cost has also been reduced.” A construction engineer also feedbacked, “When cutting concrete and red bricks, this cutting disc is particularly durable. In the past, two or three discs had to be replaced a day, but now one disc can be used for several days. It’s really practical.”

Comparison with Similar Products

Compared with similar cutting discs on the market, our 133 dry – cutting disc is superior in performance. In the wear – resistance test, its wear rate is 20% lower than that of competitors, and its service life is longer; in terms of cutting efficiency, the cutting speed has increased by 15%, which can help users complete work tasks more quickly. Moreover, our product price is more competitive, with ultra – high cost – performance, providing users with a higher – quality and more economical cutting solution.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Testimonials

WeChat Code

Site Search

Related Products

Featured Articles

© 2025. All Rights Reserved.