- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

Diamond Saw Blades

Are Diamond Saw Blades Made of Real Diamonds?

When many people first hear the term “diamond saw blade,” they might imagine a cutting tool embedded with real diamonds. However, the “diamond” in diamond saw blades is not the gemstone we know, but rather industrial-grade synthetic diamonds. In this article, we will explore the truth behind this industrial tool from three perspectives: material science, applications, and cost-effectiveness.

What Are the “Diamonds” in Diamond Saw Blades?

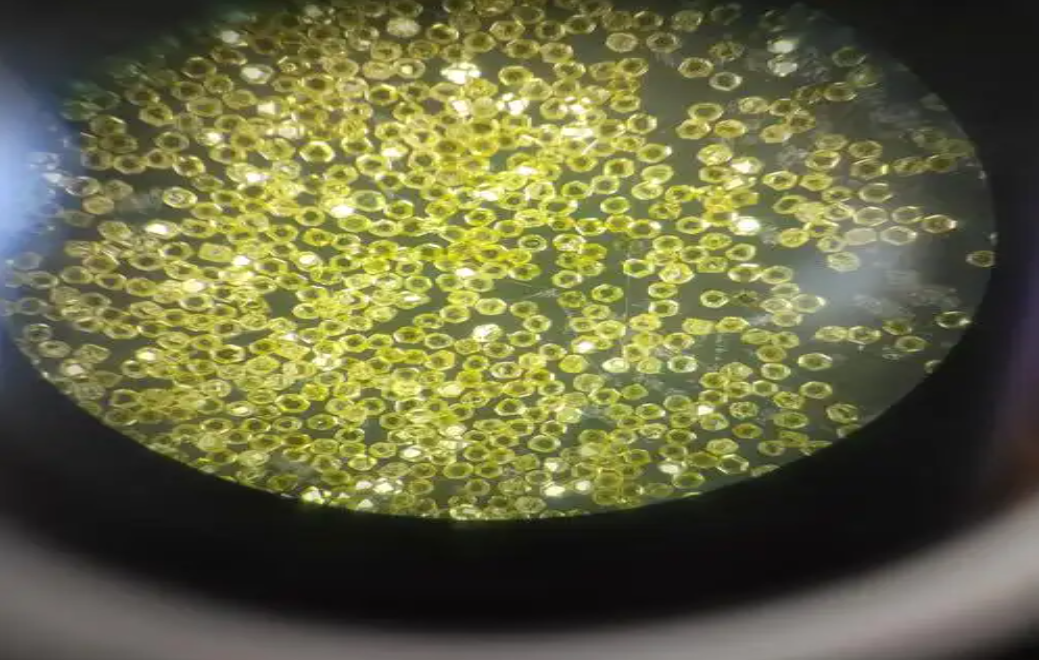

Industrial diamond saw blades use synthetic diamond powder, created through high-temperature and high-pressure synthesis. While this material shares the same carbon crystal structure as natural diamonds, its purity, size, and purpose differ significantly from gem-quality diamonds. Synthetic diamonds have a Mohs hardness of 10, identical to natural diamonds, which makes them ideal for cutting applications.

Why Use Synthetic Diamonds Instead of Real Diamonds?

From an economic standpoint, gem-quality diamonds cost thousands of dollars per carat, while synthetic diamonds are 1/50 to 1/100 of that price. More importantly, industrial cutting requires uniformly distributed micron-sized particles that are fixed to a base through electroplating or sintering processes. This structured design cannot be achieved with whole natural diamonds.

Four Key Advantages of Diamond Saw Blades

- Exceptional Hardness: Can cut hard and brittle materials like concrete and stone

- High-Temperature Resistance: Maintains performance stability at temperatures up to 800℃

- Self-Sharpening: New sharp particles are exposed as the blade wears

- Long Lifespan: Lasts 10-20 times longer than conventional abrasive blades

Industry Applications Explained

On construction sites, diamond saw blades are widely used for cutting reinforced concrete. In stone processing plants, they are essential for precision cutting of marble and granite. Even in the aerospace industry, specially designed diamond tools are used to process carbon fiber composites. These applications rely on the controlled particle size distribution and directional alignment technology of synthetic diamonds.If you have a need for diamond saw blades you can look at this one:110 Corrugated Diamond Cutting And Grinding Blades

Frequently Asked Questions (Q&A)

- Q: Do diamond saw blades become dull over time?

A: High-quality blades have a self-sharpening feature; as surface particles wear down, new particles are exposed to maintain sharpness. - Q: Can they be used for home renovation projects?

A: Yes, but it’s recommended to use smaller blades (under 300mm) with proper safety equipment. - Q: How to judge the quality of a saw blade?

A: Check the uniformity of diamond particle distribution; high-quality blades have particle spacing errors of less than 0.2mm. - Q: What is their lifespan?

A: It depends on the material being cut; for concrete, blades typically last 300-500 linear meters.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Site Search

Product Center

Testimonials

Contact Us

© 2025. All Rights Reserved.