- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+8613188737236 | Map

In the field of industrial cutting, both resin cutting disks and diamond saw blades are common cutting tools. However, they have significant differences in many aspects and cannot be simply regarded as the same.

I. Constituent Materials

(I) Resin Cutting Disks

Resin cutting disks are mainly made by using resin as a binder to bond abrasives such as corundum and silicon carbide together. The resin plays a role in fixing the abrasives and endowing the cutting disk with certain strength and toughness. Corundum abrasives have high hardness and good wear resistance, and are suitable for cutting general steel materials. Silicon carbide abrasives, on the other hand, have even higher hardness and good thermal conductivity, and are often used for cutting cast iron, non – ferrous metals, and non – metallic materials.

(II) Diamond Saw Blades

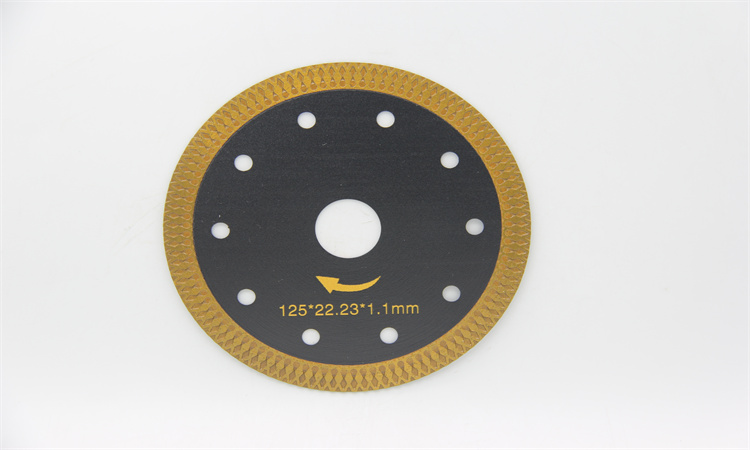

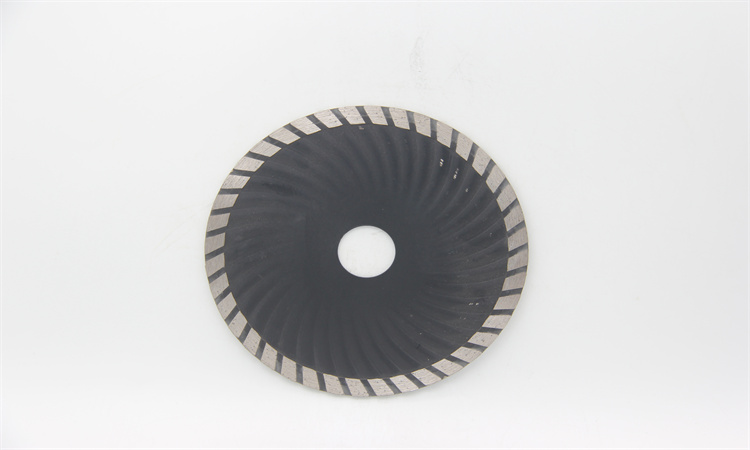

Diamond saw blades use diamond as the cutting edge material. Diamond particles are fixed on the metal substrate through processes such as sintering and electroplating. As the hardest substance in nature, diamond endows the saw blade with excellent cutting performance, enabling it to easily cut materials with extremely high hardness, such as stones, concrete, and ceramics.

II. Cutting Performance

(I) Cutting Efficiency

Thanks to its high – hardness diamond cutting edge, the diamond saw blade usually has a high cutting efficiency when cutting materials with high hardness. For example, when cutting marbles, granites, and other stones, the diamond saw blade can quickly penetrate the material, greatly shortening the cutting time. While the resin cutting disk can also have a good cutting efficiency when cutting materials with low hardness, such as ordinary steel. But for high – hardness materials, its cutting speed will slow down significantly.

(II) Cutting Precision

Due to the relatively small and evenly distributed abrasive particles, the resin cutting disk can achieve good cutting precision when cutting some metal materials with high precision requirements, and the cutting surface is relatively flat and smooth. However, after special processing, the diamond saw blade can also achieve high precision when cutting materials with high – precision requirements, such as optical glass and semiconductor materials. Moreover, due to the wear resistance of diamond, it can better maintain the cutting precision during long – term cutting.

(III) Wear Resistance

The wear resistance of diamond saw blades is far superior to that of resin cutting disks. The high hardness of diamond makes its wear extremely slow during the cutting process, enabling it to maintain good cutting performance for a long time and is suitable for a large amount of cutting work. While during the cutting process of the resin cutting disk, the abrasives will gradually wear and fall off, resulting in a relatively short service life and the need for frequent replacement.

III. Application Scope

(I) Resin Cutting Disks

Due to the characteristics of its abrasives and binder, the resin cutting disk is more suitable for cutting metal materials, such as various steels and aluminum alloys. At the same time, it can also effectively cut some thin non – metallic materials, such as plastic sheets and thin wooden boards.

(II) Diamond Saw Blades

Diamond saw blades are mainly used for cutting materials with high hardness, such as cutting stones and concrete in the construction industry, and cutting brittle materials such as ceramics and glass in the industrial field. In some special metal processing, such as cutting hard – to – machine materials like cemented carbide, diamond saw blades can also play an important role.

IV. Price and Cost

(I) Price

Generally, the price of diamond saw blades is relatively high. This is because diamond itself has a high value, and the process of fixing diamond on the substrate is relatively complex. While the raw material cost of resin cutting disks is relatively low, and the manufacturing process is relatively simple, so the price is more affordable.

(II) Comprehensive Cost

Although diamond saw blades are expensive, due to their good wear resistance and long service life, the comprehensive cost may be lower in large – scale and long – term cutting work. For example, in large – scale stone processing plants, although the one – time investment in using diamond saw blades is relatively large, the frequency of saw blade replacement is low, which can improve production efficiency and reduce the overall cost. While the resin cutting disk, although having a low unit price, needs to be replaced frequently due to rapid wear, which may increase the cost in the long – term use.

In conclusion, resin cutting disks and diamond saw blades have obvious differences in constituent materials, cutting performance, application scope, price, and cost. They are not the same. In practical applications, it is necessary to reasonably select the appropriate cutting tool according to specific cutting requirements, material characteristics, and budget factors to achieve the best cutting effect and economic benefits.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Site Search

Product Center

Testimonials

Contact Us

© 2025. All Rights Reserved.