- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

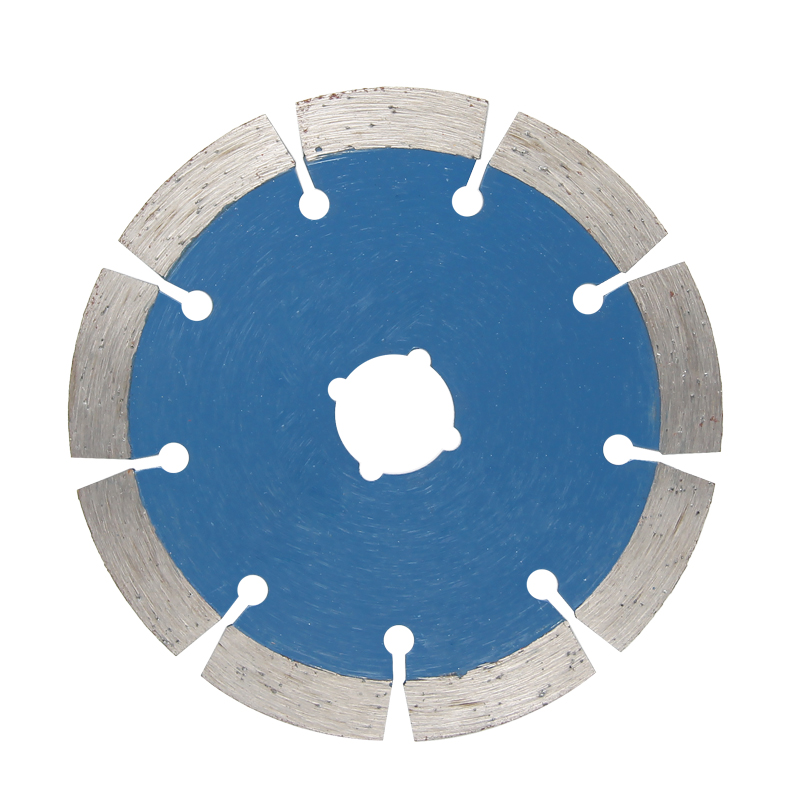

Deep Hole 110 Dry Slicing General Purpose Diamond Saw Blades

- Category: Products, Stone Cutting Blades

- |

- Date: 01/18/2025 20:57

Deep Hole 110 Dry Slicing General Purpose Diamond Saw Blades

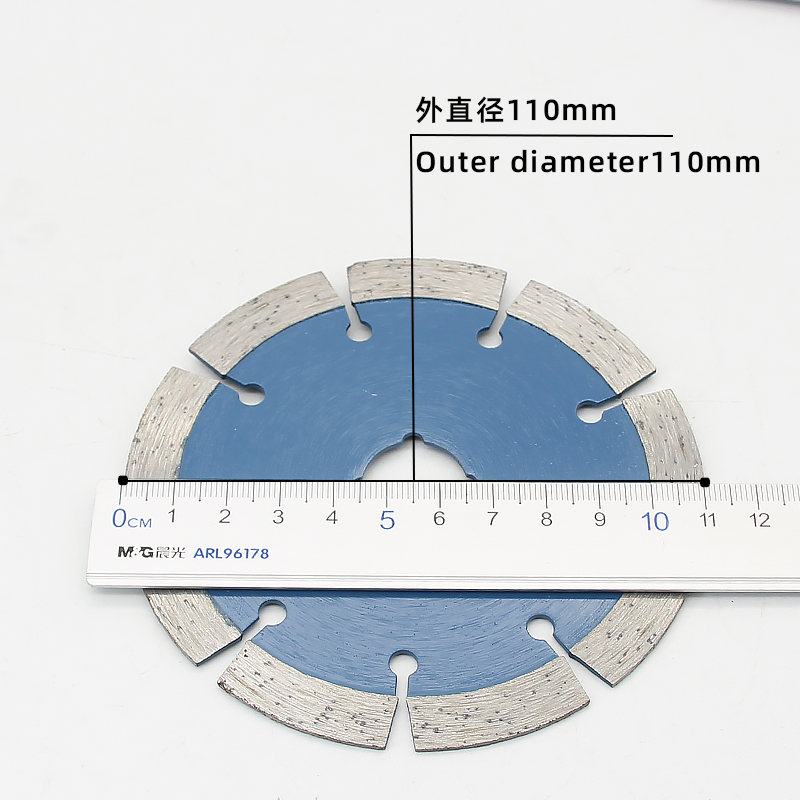

- Diameter: 110mm

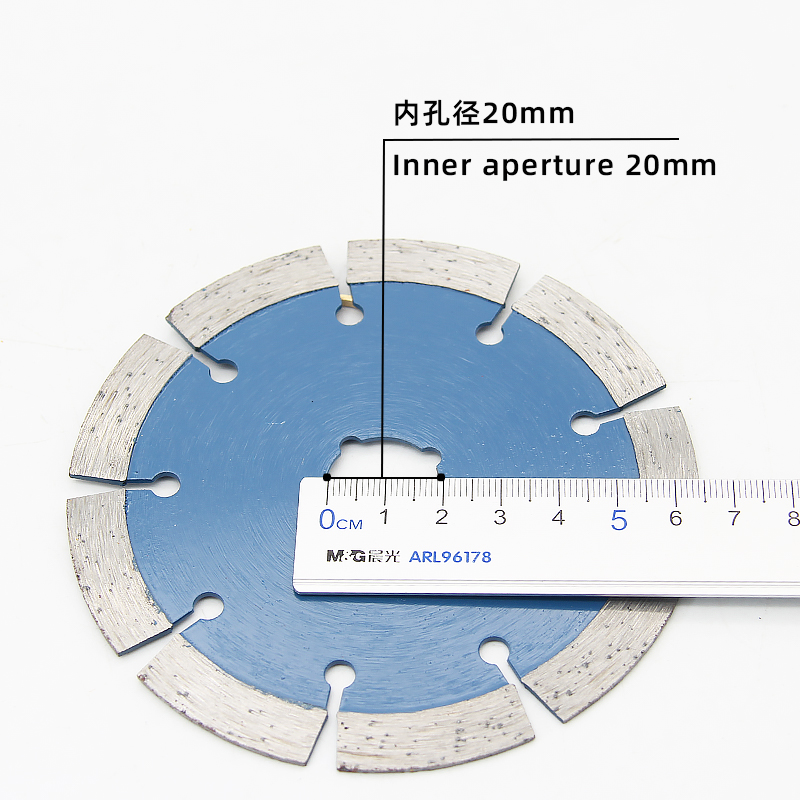

- Hole diameter: 20mm

- Head height: 10mm

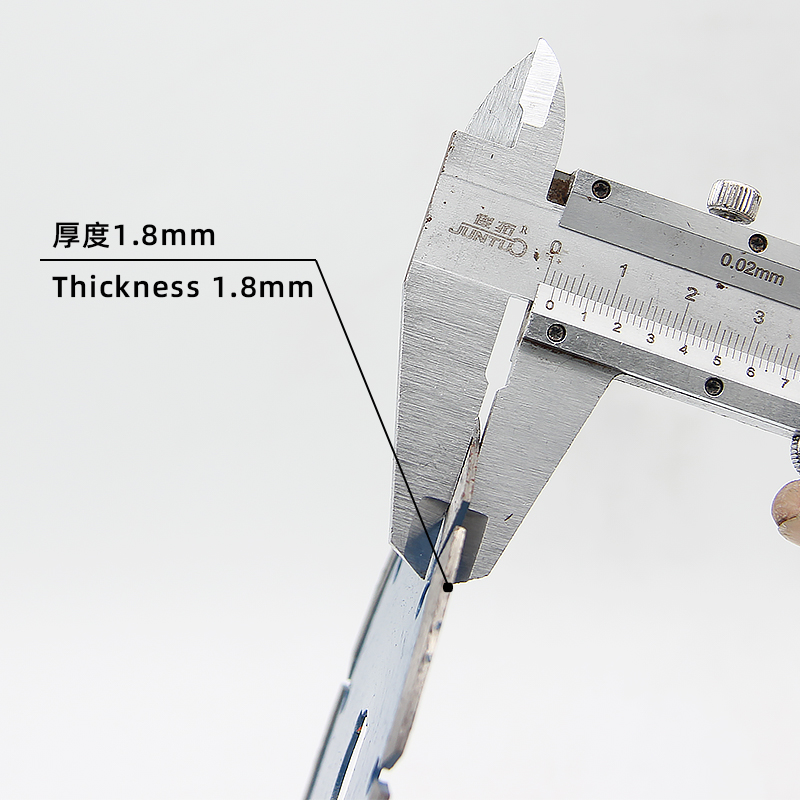

- Thickness: 1.8mm

- Place of origin: China, Shandong, Linyi

- Applications: granite, sandstone, rock slabs, marble cutting.

Product Details

The following is a detailed introduction to 110 dry slicing universal diamond saw blades, and its bore adopts the design of Bo deep hole:

I. Basic Concept

110 Dry Slicing Universal Diamond Saw Blade is a tool specially designed for cutting stone, ceramics, glass and other hard and brittle materials. Its diameter is usually 110 millimeters, which is suitable for all kinds of angle grinders, cutters and other equipment. And the inner hole is designed with Boshen hole, which means the center hole of the saw blade is designed and manufactured according to the specific standard or technology of Boshen Company.

Second, the main features

Efficient Cutting: With its sharp cutting edge and excellent abrasion resistance, diamond saw blades can efficiently complete cutting tasks and improve productivity.

Strong versatility: 110mm diameter makes this saw blade widely applicable for cutting a wide range of materials and workpieces of different thicknesses.

Bo-Deep Hole Design: The bo-deep hole design of the bore may mean better stability and durability of the saw blade during installation and use. This design helps to reduce vibration and noise when the saw blade is rotating at high speeds, improving cutting accuracy and safety.

Wear-resistant and durable: diamond saw blades have extremely high hardness and wear-resistant, which can maintain excellent cutting performance during a long time of use.

Application Scenario

110 dry slicing general-purpose diamond saw blades are suitable for cutting and processing of various hard and brittle materials such as stone, ceramics and glass. For example, in the construction industry, it can be used to cut marble, granite and other stone materials; in the decoration industry, it can be used to cut ceramic tiles, glass and other materials. In addition, this kind of saw blade is also suitable for handicraft production, artwork carving and other fields.

Fourth, the use of precautions

Choose the right equipment: Make sure the angle grinder or cutter used matches the specification of the saw blade to avoid overloading or damaging the equipment.

Install the saw blade correctly: when installing the saw blade, make sure that the saw blade fits closely with the flange of the equipment to avoid loosening or falling off. At the same time, the saw blade should be installed correctly according to the instruction manual of the equipment to ensure its stability and safety.

Maintain proper cutting speed: During the cutting process, proper cutting speed should be maintained to avoid too fast or too slow resulting in poor cutting results or damage to the saw blade.

Replace worn saw blades in time: In the course of use, the wear of saw blades should be checked regularly. Once the saw blade is found to be seriously worn or damaged, it should be replaced with a new one in time to ensure cutting quality and safety.

To summarize, 110 dry slicing universal diamond saw blade is a kind of efficient and versatile cutting tool, and its bore adopts bo deep hole design, which makes the saw blade have better stability and durability. When using, attention should be paid to choosing the right equipment, installing the saw blade correctly, maintaining the proper cutting speed and replacing the worn out saw blade in time.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Testimonials

Site Search

Product Center

Testimonials

Contact Us

© 2025. All Rights Reserved.