- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

Veteran contractor John recently faced a headache – his new wall saw blade showed significant wear after just three days of use. This raises the question: Can we really only extend wall saw blade lifespan through frequent replacements? Today we reveal professional maintenance secrets from construction crews.

I. Proper Operation: The Foundation of Longevity

1. RPM Matching Essentials

Test data shows that when blade speed exceeds rated RPM by 20%, wear rate triples. Recommended RPM settings by material:

- Concrete walls: 3000-3500 RPM

- Brick walls: 2800-3200 RPM

- Lightweight partitions: Below 2500 RPM

2. Cutting Angle Techniques

Maintain 90-degree vertical alignment. When encountering rebar, pause and use side-to-side rocking motion to pass through slowly, avoiding direct impact on teeth.

II. Maintenance Golden Rules

1. Cleaning Protocol

After each use, clean blade slots with stiff brush + air gun. Pay special attention to cement residue – these “silent killers” accelerate diamond segment loss.

2. Cooling Lubrication

For continuous operation over 15 minutes, adopt wet cutting method: Spray coolant every 2 meters to reduce friction heat and dust.

3. Storage Solutions

Store blades in dry anti-rust cases. Avoid stacking. Apply rust inhibitor and separate teeth with corrugated paper for long-term storage.

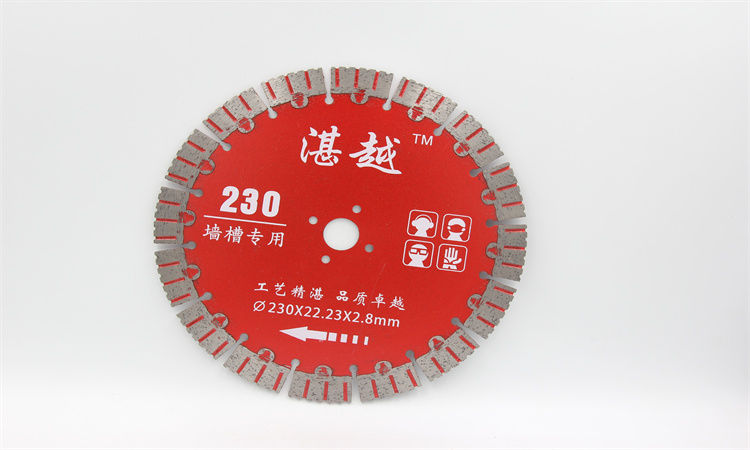

III. Blade Selection Secrets

Beyond price and diameter, focus on diamond concentration (30%-40% recommended) and welding technology (laser welding outperforms high-frequency).

IV. Special Scenario Tactics

For mixed-material walls in old buildings, use “pre-drill & cut” method: Drill holes along cutting line before sawing, reducing blade stress by 50%.

Q&A Section

Q: When must blades be replaced?

A: Replace when diamond segments wear beyond 2/3 thickness or blade warping occurs.

Q: Can I sharpen blades myself?

A: Not recommended for professional blades. DIY blades can use diamond files for tooth reshaping.

Q: Winter usage tips?

A: Warm up blades by idling 1-2 minutes before cutting to prevent cold fractures.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Site Search

Product Center

Testimonials

Contact Us

© 2025. All Rights Reserved.