- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

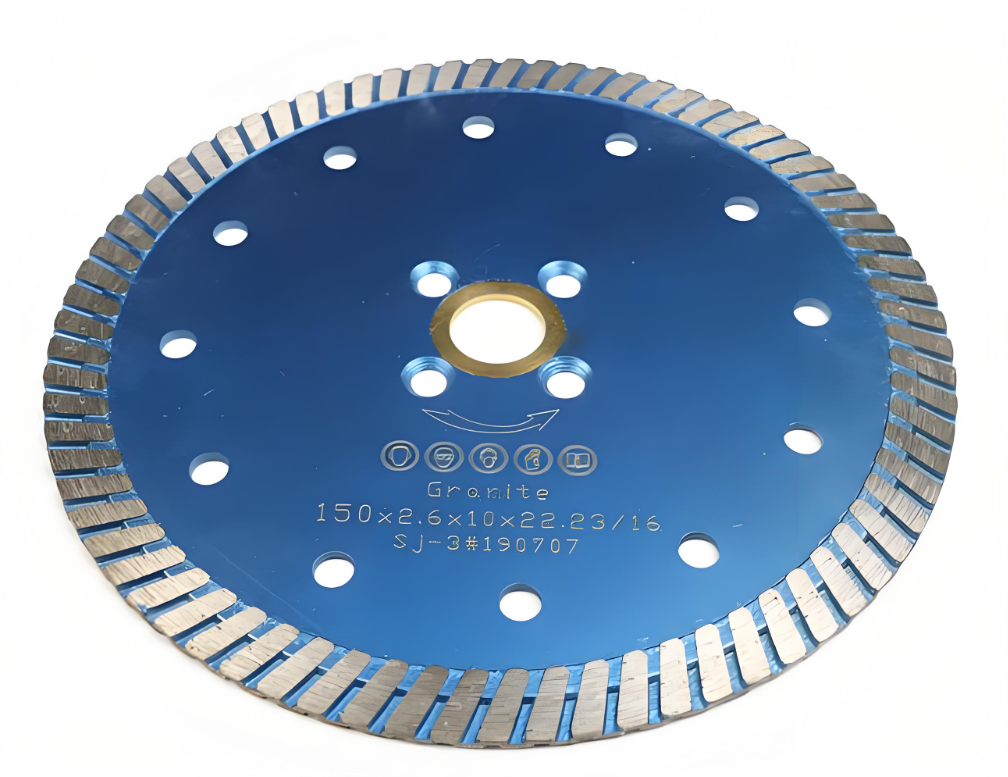

Maintaining Diamond Blades

Why Do Diamond Blades Require Professional Maintenance?

While diamond blades excel at cutting hard materials like stone and ceramic due to their ultra-hard composition, their high cost makes maintaining diamond blades essential. Poor maintenance leads to blade dulling, matrix deformation, and operational safety risks.

How to Maintain Diamond Blades: Step-by-Step Guide

Step 1: Daily Cleaning & Debris Removal

After each use, scrub blade slots with a stiff-bristled brush to remove particles. Soak stubborn residue in specialized cleaning solution for 10 minutes before rinsing.

Step 2: Proper Installation & Usage

Ensure flange diameter ≥ 1/3 of blade size. Tighten bolts with a torque wrench as specified. Maintain continuous water flow during cutting to prevent diamond segment detachment.

Step 3: Scientific Storage Methods

Store vertically in dedicated blade racks with 40%-60% humidity. Apply rust inhibitor and wrap in bubble film for long-term storage.

Advanced Maintenance Techniques

Regular Dressing Treatment

After 50 cutting hours or when efficiency drops, use basalt dressing stones at 15-degree angle to restore diamond grit sharpness.

Dynamic Balance Testing

Quarterly check blade wobble with dynamic balancers. Correct if deviation exceeds 0.02mm. Unbalanced blades increase bearing wear and energy consumption by 30%+.

Frequently Asked Questions (Q&A)

Q: How to treat rust spots on blades?

A: Gently sand with 1200-grit paper, apply WD-40, and store with desiccant packs.

Q: Are cutting sparks normal?

A: Absolutely not! Indicates insufficient coolant or excessive pressure – stop immediately and check cooling systems.

Q: Typical blade lifespan?

A: With proper maintenance, 10″ blades cut 800-1200 linear meters of granite, depending on usage frequency and material hardness.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Site Search

Product Center

Testimonials

Contact Us

© 2025. All Rights Reserved.