- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

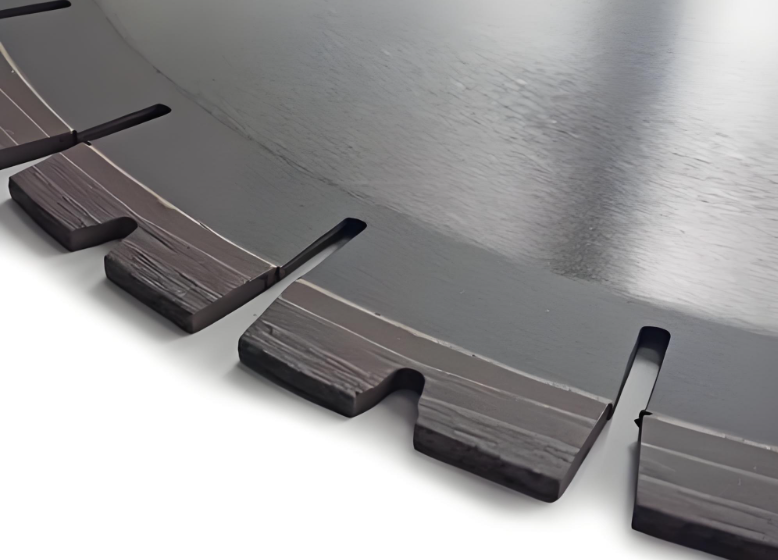

Diamond Blade Manufacturers

Global Challenges for Export Diamond Blade Manufacturers

As global industrial demand grows, diamond blade manufacturers aiming to compete internationally must overcome technological barriers, comply with multinational standards, and establish efficient cross-border service systems. This article reveals five critical advantages defining successful export diamond blade manufacturers.

Advantage 1: Cutting-Edge R&D Capabilities

To thrive globally, diamond blade manufacturers must continuously invest in laser welding technology and superhard material synthesis. For instance, developing region-specific formulas tailored to local stone hardness significantly enhances product adaptability.

Advantage 2: International Certification Compliance

Exporters must obtain CE certification, OSHA standards, and other approvals. Statistics show that export diamond blade manufacturers with multinational certifications achieve 40% higher overseas order conversion rates.

Advantage 3: Globalized Supply Chain Management

Building overseas warehouses and localized service teams is crucial. Regional distribution centers in key markets enable 72-hour emergency response times, dramatically improving client satisfaction.

Building Sustainable Export Competitiveness

Beyond technical strengths, top-tier diamond blade manufacturers prioritize:

- Multilingual digital marketing systems

- Real-time monitoring of regional regulations

- Digitized cross-border after-sales services

Case Study: Market Leader’s Success Strategy

A leading export diamond blade manufacturer achieved 217% growth in European market share over three years through 3D-printed blade structures and a blockchain-based logistics tracking system.

Frequently Asked Questions

Q: What certifications are essential for exporting diamond blades?

A: Minimum requirements include CE certification and ISO 9001 QMS. Specific markets may require UL or RoHS compliance.

Q: How to prevent product damage during international shipping?

A: Use shock-resistant vacuum packaging with environmental sensors, and establish quality compensation agreements with local logistics partners.

Q: How can small manufacturers enter global markets?

A: Focus on single-region penetration via e-commerce platforms combined with targeted trade show participation.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Site Search

Product Center

Testimonials

Contact Us

© 2025. All Rights Reserved.