- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+85261041051 | Map

4-Inch Marble Cutting Blade

In the stone processing industry, the 4-inch marble cutting blade is a common and efficient tool. Whether you are a professional craftsman or a DIY enthusiast, choosing the right cutting material is crucial for improving work efficiency and safety. So, what is the best cutting material for a 4-inch marble cutting blade? This article will provide a detailed analysis.

Best Cutting Materials for Marble Cutting Blades

To understand the best cutting materials for marble cutting blades, it is first necessary to understand the characteristics of marble and the requirements for cutting. Marble is a natural stone with high hardness, so it is important to choose cutting blade materials that are wear-resistant and moderately hard. Below are some common cutting blade materials and their suitability:

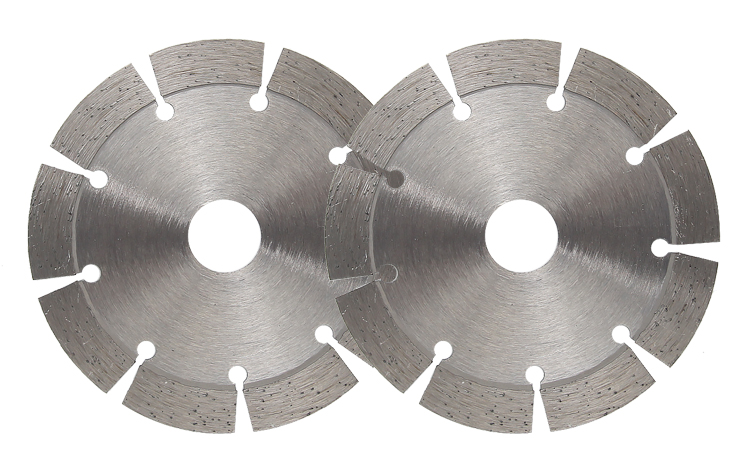

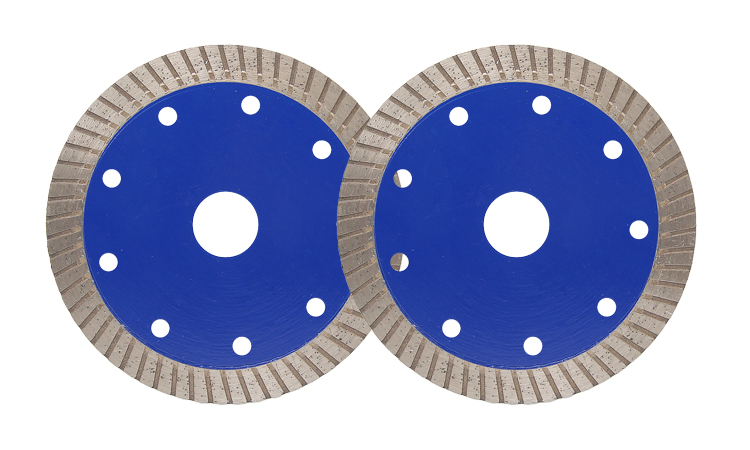

1. Diamond Cutting Blades

Diamond is one of the hardest materials known, making diamond cutting blades the preferred choice for cutting marble. Diamond particles are embedded into the edge of the blade, allowing for efficient cutting of marble while maintaining a long lifespan. For 4-inch marble cutting blades, diamond blades not only cut quickly but also with high precision, making them ideal for fine processing.

2. Silicon Carbide Cutting Blades

Silicon carbide is a material with hardness second only to diamond and is commonly used for cutting medium-hard stones. While silicon carbide blades perform well when cutting marble, their wear resistance is not as good as diamond blades. Therefore, silicon carbide blades are more suitable for users with limited budgets or smaller cutting volumes.

3. Aluminum Oxide Cutting Blades

Aluminum oxide blades are an economical option suitable for cutting softer stones. However, for harder marble, aluminum oxide blades are less efficient and wear out quickly. Therefore, aluminum oxide blades are not recommended as the primary choice for 4-inch marble cutting blades.

How to Choose the Right 4-Inch Marble Cutting Blade?

When selecting a 4-inch marble cutting blade, in addition to the material, the following factors should also be considered:

1. Blade Thickness

The thickness of the blade directly affects cutting precision and speed. Thinner blades are suitable for fine cutting, while thicker blades are better for quickly cutting large stone blocks.

2. Blade Tooth Design

Different tooth designs are suitable for different cutting needs. For example, continuous teeth are ideal for smooth cutting, while segmented teeth are better for fast cutting.

3. Blade Brand and Quality

Choosing blades from reputable brands ensures quality and safety. Low-quality blades are not only inefficient but may also pose safety risks.

Precautions for Using 4-Inch Marble Cutting Blades

To ensure safety and efficiency during the cutting process, the following precautions should be taken when using a 4-inch marble cutting blade:

- Wear protective gear, such as goggles and gloves.

- Ensure the blade is securely installed to avoid loosening.

- Maintain stable force and speed during cutting to avoid excessive pressure.

- Regularly check the blade for wear and replace it promptly.

Q&A Section

Q1: Can a 4-inch marble cutting blade cut other materials?

A1: Yes, a 4-inch marble cutting blade can also be used to cut other materials with similar hardness, such as granite or tiles. However, note that the cutting results may vary depending on the material.

Q2: Are diamond cutting blades more expensive?

A2: Yes, diamond cutting blades are relatively more expensive, but their long lifespan and high cutting efficiency make them cost-effective in the long run.

Q3: How do I know when to replace the cutting blade?

A3: When the cutting efficiency of the blade significantly decreases, or if abnormal vibrations and noises occur during cutting, it may be time to replace the blade.

Q4: Is water cooling necessary when cutting marble?

A4: Yes, water cooling reduces blade wear and prevents the stone from cracking due to high temperatures.

Q5: Is a 4-inch marble cutting blade suitable for home use?

A5: Yes, the 4-inch marble cutting blade is compact and easy to operate, making it ideal for home DIY projects.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Site Search

Product Center

Testimonials

Contact Us

© 2025. All Rights Reserved.