- Welcome to, we are a factory specializing in the production and manufacture of saw blades!

- WhatsApp:+8613188737236 | Map

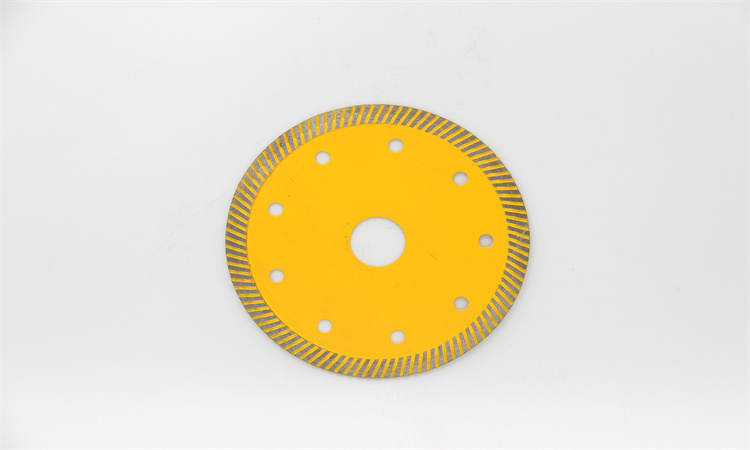

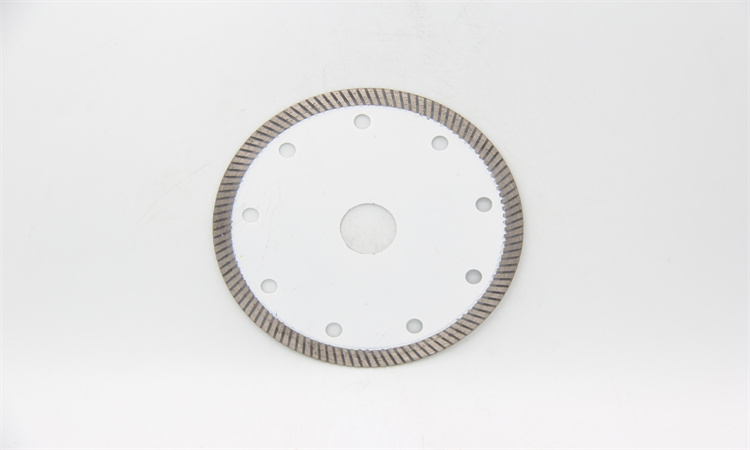

Among numerous cutting tool materials, diamond stands out as an ideal choice for cutting operations in both industry and daily life. This is mainly attributed to its unique physical and chemical properties, which endow diamond with excellent cutting performance.

I. Extremely High Hardness

Diamond has the highest hardness among known substances in nature, with a Mohs hardness of 10. This extremely high hardness enables diamond to easily scratch and wear other materials while remaining almost un-worn itself. When used for cutting, diamond can generate sufficient pressure on the surface of the material being cut, causing local fragmentation or plastic deformation, thus achieving the purpose of cutting. In contrast, ordinary cutting tools, such as hacksaw blades, have a much lower hardness than diamond. When cutting materials with relatively high hardness, the saw blade itself will wear out rapidly, resulting in a decrease in cutting efficiency and cutting quality.

II. Good Wear Resistance

Diamond is not only hard but also has excellent wear resistance. During the cutting process, there is intense friction between the tool and the material being cut, which causes the material on the surface of the tool to gradually wear away. Due to the extremely stable atomic structure of diamond and the strong carbon-carbon bond energy, it can maintain a relatively stable shape and size during long-term friction, greatly extending the service life of the cutting tool. For example, in the stone processing industry, diamond saw blades used to cut marble and other stones have a much longer service life than ordinary saw blades. They can still maintain good cutting performance after continuously cutting a large amount of stone.

III. High Thermal Conductivity

Diamond has extremely high thermal conductivity, with a thermal conductivity higher than that of many metals. During the cutting process, a large amount of heat is generated due to friction. If this heat cannot be dissipated in a timely manner, the temperature in the cutting area will rise sharply, affecting the cutting quality and even potentially damaging the cutting tool. The high thermal conductivity of diamond allows it to quickly transfer heat, effectively reducing the temperature in the cutting area and minimizing the risk of thermal deformation and thermal damage. This is particularly important for cutting temperature-sensitive materials such as optical glass and semiconductor materials, ensuring that the cut materials maintain high precision and good surface quality.

IV. Sharp Cutting Edge

Diamond can be made into cutting tools with extremely sharp cutting edges through special processing techniques. The regularity and stability of its atomic structure enable the formation of sharp microstructures at the cutting edge. These sharp cutting edges can more easily penetrate the material being cut, reducing the force required for cutting and improving cutting efficiency. For example, diamond tools can achieve micron or even nanometer-level cutting accuracy in precision machining, meeting the stringent requirements of high-end manufacturing for the machining accuracy of components.

V. Chemical Stability

Diamond has good chemical stability under normal temperature and pressure and is not prone to chemical reactions with other substances. This property enables diamond cutting tools to maintain stable performance in various working environments. Whether cutting wood or stone in a humid environment or performing cutting operations in a corrosive chemical solution, diamond will not reduce its cutting performance due to chemical corrosion, ensuring the reliability and durability of the cutting tool.

In conclusion, diamond has become an unparalleled cutting tool due to its extremely high hardness, good wear resistance, high thermal conductivity, sharp cutting edge, and chemical stability. In many fields such as modern industrial production, construction, and jewelry processing, diamond cutting tools play an indispensable role, driving the technological progress and development of various industries.

Although diamond has obvious advantages in the cutting field, the specific requirements for its cutting tools vary in different application scenarios. If you can provide more specific application scenarios, such as industrial metal cutting or jewelry processing, I can further explore the unique features of diamond as a cutting tool in that scenario.

Zhanyuetool

Shandong Zhan Yue Tools Co.

Site Search

Product Center

Testimonials

Contact Us

© 2025. All Rights Reserved.